Top 10 Mono Carton Box Manufacturers In India 2026: Prices, Features, Design, and HSN Codes

Top 10 Mono Carton Box Manufacturers In India 2026: Prices, Features, Design, and HSN Codes

Mono carton boxes are one of the most widely used packaging solutions across industries such as FMCG, cosmetics, pharmaceuticals, electronics, food, and retail. These boxes are typically made from paperboard or duplex board and are printed, folded, and glued to create lightweight yet durable packaging. With the rapid growth of e-commerce and branded retail in India, the demand for mono cartons has increased significantly in 2026 due to their affordability, customization options, and eco-friendly properties. If you are looking to buy mono carton boxes in bulk at wholesale prices, Moglix is the right platform to procure them efficiently.

In this detailed guide, you will learn about the top mono carton box manufacturers in India, pricing, design features, materials, and HSN codes.

What Is a Mono Carton Box?

A mono carton box is a single-layer folding carton made from paperboard or duplex board. These boxes are commonly used for product packaging and branding.

Key Characteristics

- Lightweight and cost-effective

- Fully printable surface for branding

- Easy to fold and assemble

- Eco-friendly and recyclable

- Available in custom sizes and designs

Top 10 Mono Carton Box Manufacturers In India (2026)

Below are some of the most trusted manufacturers and suppliers of mono carton boxes in India.

1. TCPL Packaging Ltd.

TCPL Packaging is one of India’s leading carton packaging companies specializing in folding cartons and printed mono cartons. It serves industries such as liquor, pharmaceuticals, FMCG, and food packaging.

Key Features

- High-quality offset printing

- Automated production lines

- Premium design solutions

- Strong supply chain network

Price Range: ₹8 – ₹40 per piece, depending on size and printing.

2. Kapco Packing Company

Kapco is known for luxury mono cartons and high-quality folding cartons used for premium product packaging.

Specialization

- Luxury packaging

- Cosmetic boxes

- Custom die-cut cartons

3. Canpac Trends Pvt. Ltd.

Canpac Trends offers complete packaging solutions including mono cartons, flexible packaging, and custom printed cartons.

Best For

- FMCG packaging

- Industrial packaging

- Custom branding

4. TGI Packaging Pvt. Ltd.

TGI Packaging is a well-known exporter of printed mono cartons and corrugated packaging products.

Key Features

- Export quality standards

- Innovative packaging design

- Durable carton materials

5. Trident Paper Box Industries

This company manufactures paperboard cartons, corrugated cartons, and mono cartons.

Specialization

- Printed cartons

- Pharmaceutical packaging

- Food packaging boxes

6. Om Shanthi Packaging Industries

A reputed packaging company offering duplex and mono cartons with advanced manufacturing equipment.

Key Highlights

- High-speed printing machines

- Custom size options

- Strong structural design

7. Multi Pack Industries

Multi Pack is known for affordable custom mono cartons and bulk packaging solutions.

Key Benefits

- Competitive pricing

- Bulk supply capability

- High durability cartons

8. Aaradhya Enterprises

Aaradhya Enterprises manufactures mono cartons mainly for food, beverages, and retail industries.

Key Features

- Eco-friendly materials

- Strong packaging quality

- Custom printing support

9. Hariwansh Packing Pvt. Ltd.

A one-stop packaging solution provider offering customized mono cartons.

Strengths

- Customized partitions

- Structural packaging design

- High-quality paperboard

10. Carton Box Manufacturing Industries

This company specializes in printed mono cartons and heavy-duty packaging solutions.

Best For

- Industrial packaging

- Heavy product cartons

- Bulk orders

(Manufacturers list sourced from packaging supplier directories.)

Check out the Mono Carton Box Price In India (2026)

Prices depend on material, printing quality, and size.

Average Price Range

| Type | Price Range |

| Plain mono cartons | ₹5 – ₹15 per piece |

| Printed cartons | ₹8 – ₹40 per piece |

| Premium laminated cartons | ₹20 – ₹80 per piece |

| Custom luxury cartons | ₹50 – ₹200 per piece |

Pricing varies based on bulk orders, GSM thickness, and printing technology.

What Materials are Used In Mono Carton Boxes?

Common materials include:

- Duplex board

- SBS paperboard

- Kraft paperboard

- Corrugated single-wall board

- Recycled paperboard

Understand the Design Features Of Mono Cartons

Mono cartons offer advanced design flexibility.

Popular Design Options

- Window cut designs

- Embossing and debossing

- Matte and gloss lamination

- UV coating and foil stamping

- Die-cut custom shapes

These features enhance brand visibility and shelf appeal.

Applications Of Mono Carton Boxes

Mono cartons are widely used in multiple industries.

Major Applications

- FMCG packaging

- Cosmetic product boxes

- Pharmaceutical packaging

- Food packaging cartons

- Electronics packaging

- Retail product packaging

Quick Look at HSN Codes For Mono Carton Boxes

Mono carton boxes fall under Chapter 48 of the GST classification.

Important HSN Codes

- HSN Code 481910 – Cartons, boxes, cases, and packing containers of paper or paperboard

- GST Rate: 12%

- HSN Code 48196000 – Paperboard box files and packaging containers

- GST Rate: 12%

Have A Glance At The Benefits Of Using Mono Carton Packaging

1. Cost-Effective Packaging

Mono cartons are cheaper compared to rigid boxes and plastic packaging.

2. Eco-Friendly

Made from recyclable paperboard materials.

3. Branding Friendly

Excellent surface for printing logos and designs.

4. Lightweight Yet Strong

Provides good protection without adding shipping weight.

Future Trends In Mono Carton Packaging (2026)

Key trends shaping the industry include:

- Sustainable packaging solutions

- Smart QR code printed cartons

- Digital printing technology

- Lightweight high-strength materials

- Custom luxury packaging designs

Conclusion

Mono carton boxes are essential for modern product packaging due to their affordability, durability, and branding capabilities. India has a strong packaging manufacturing ecosystem with numerous reliable mono carton suppliers offering customized solutions for every industry. By understanding manufacturers, pricing, features, and HSN codes, businesses can choose the best packaging partner, like the Moglix packaging solution in 2026.

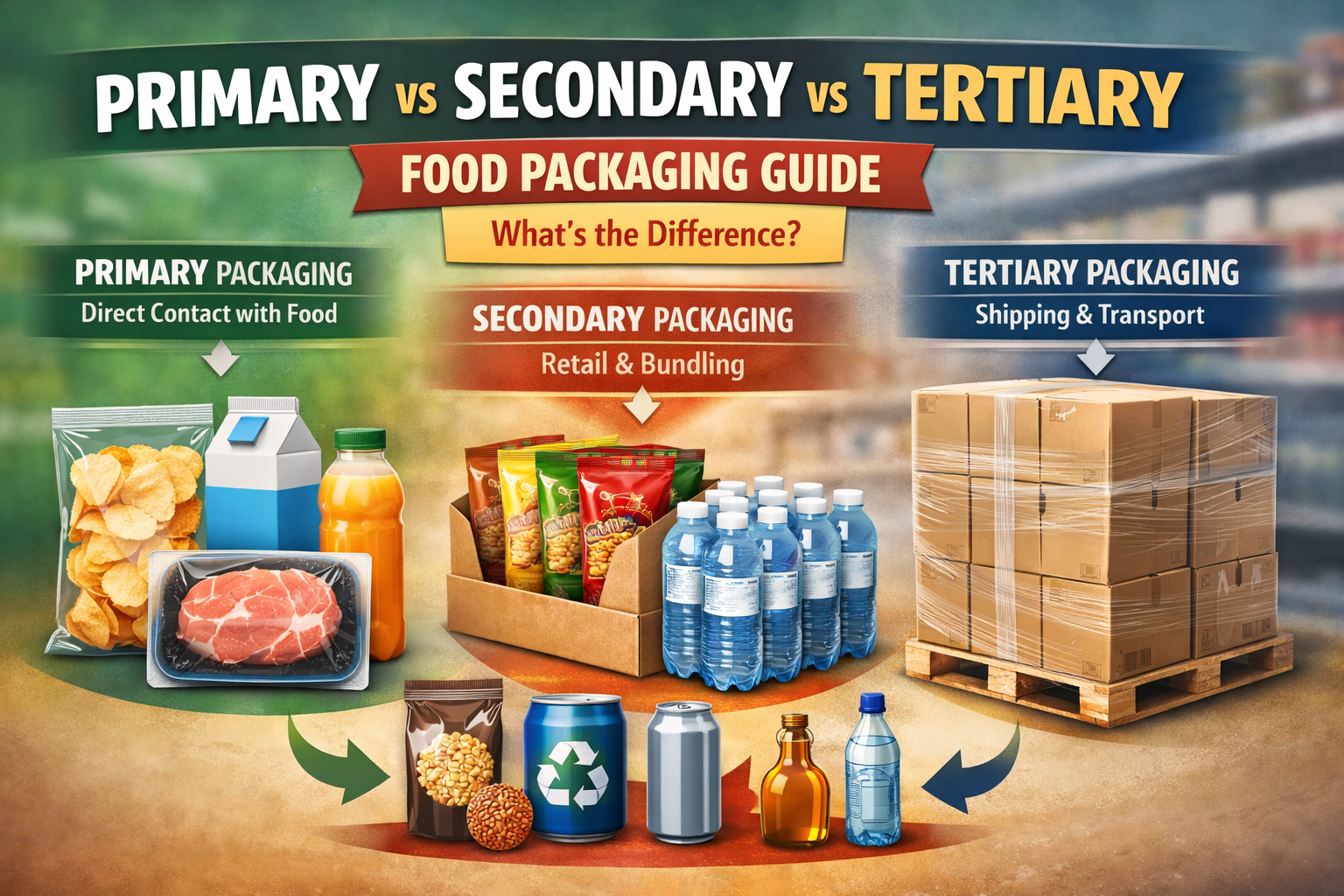

Primary vs Secondary vs Tertiary Food Packaging – What’s the Difference?

Primary vs Secondary vs Tertiary Food Packaging – What’s the Difference?

Food packaging plays a critical role in protecting products, extending shelf life, ensuring compliance, and enhancing brand visibility. Whether you’re a food manufacturer, distributor, or D2C brand, understanding the different levels of packaging helps you optimize cost, safety, and logistics.

In this guide, we’ll break down:

- Primary vs Secondary vs Tertiary packaging

- How to choose the right packaging for different food categories

- Best packaging solutions for dry foods

- Beverage packaging options (PET, glass, cans & sustainable alternatives)

- Top FAQs & People Also Ask

What Is Primary, Secondary, and Tertiary Food Packaging?

Primary Packaging (Consumer Packaging)

Primary packaging is the first layer that directly comes in contact with the food product.

Purpose:

- Protect from contamination

- Preserve freshness

- Provide essential product information

- Enhance shelf appeal

Examples:

- Snack pouches

- Milk cartons

- PET bottles

- Vacuum-sealed meat packs

- Chocolate wrappers

It must comply with food safety standards and be made from food-grade materials.

Secondary Packaging (Outer Packaging)

Secondary packaging groups multiple primary packages together for display, branding, and retail handling.

Purpose:

- Protect primary packaging

- Improve shelf organization

- Support branding & promotions

Examples:

- Corrugated cartons holding multiple juice bottles

- Shrink-wrapped water bottle packs

- Printed display boxes for snack bars

Tertiary Packaging (Transport Packaging)

Tertiary packaging is used for bulk handling, warehousing, and transportation.

Purpose:

- Protect goods during shipping

- Enable stacking and palletization

- Reduce transit damage

Examples:

- Palletized cartons

- Stretch-wrapped bulk shipments

- Industrial shipping crates

Quick Comparison Table

| Type | Direct Contact with Food | Purpose | Example |

| Primary | Yes | Protection & preservation | Chips pouch |

| Secondary | No | Grouping & branding | Carton of 12 juice bottles |

| Tertiary | No | Bulk transport | Palletized boxes |

How to Choose the Right Packaging for Different Food Categories

Choosing the right packaging depends on:

1. Shelf Life Requirements

- Long shelf life → Use barrier materials (multi-layer laminates, vacuum packs, MAP technology)

- Short shelf life → Lightweight and breathable materials may work

2. Moisture & Oxygen Sensitivity

- Dry foods need moisture barriers

- Oils & beverages require oxygen barriers

3. Storage & Transportation Conditions

- Frozen food → Cold-resistant packaging

- Export goods → Strong tertiary packaging

4. Regulatory Compliance

Ensure materials meet food safety standards (FSSAI or relevant regulatory bodies).

5. Branding & Consumer Experience

- Transparent windows for visibility

- Easy-tear & resealable features

- Eco-friendly claims for sustainability-conscious buyers

Best Packaging Solutions for Dry Foods (Grains, Pulses, Snacks)

Dry foods require protection from moisture, air, insects, and contamination.

Grains & Pulses

Recommended Packaging:

- Multi-layer laminated pouches

- BOPP or PP woven sacks (bulk)

- Vacuum-sealed packs for premium branding

- Stand-up zipper pouches

- Leak-proof food containers

Key Features Needed:

- Moisture barrier

- Tear resistance

- Resealability for consumer convenience

Snacks (Chips, Namkeen, Biscuits)

Recommended Packaging:

- Metalized polyester laminated pouches

- Nitrogen-flushed packs

- Pillow pouches

- Printed stand-up pouches

Why?

Snacks are sensitive to oxygen and moisture, which affect crispiness. Nitrogen flushing helps maintain freshness.

Beverage Packaging – PET, Glass, Cans & Sustainable Alternatives

Beverage packaging must ensure leak-proof storage, pressure resistance, and shelf stability.

PET Bottles

Best For: Water, soft drinks, juices

Advantages:

- Lightweight

- Cost-effective

- Shatter-resistant

- Recyclable

Limitation: Lower premium perception compared to glass.

Best For: Premium juices, dairy drinks, alcoholic beverages

Advantages:

- Excellent barrier properties

- 100% recyclable

- Premium appeal

Limitation: Heavy & fragile

Aluminum Cans

Best For: Carbonated beverages, energy drinks

Advantages:

- Excellent oxygen & light barrier

- Fast cooling

- Highly recyclable

Sustainable Alternatives

- Plant-based bio-plastics (PLA)

- Recycled PET (rPET)

- Paper-based bottles

- Returnable glass systems

Many brands are shifting toward circular packaging models to reduce their carbon footprint.

Top FAQs – Food Packaging

What is the difference between primary and secondary packaging?

Primary packaging directly contacts food; secondary packaging groups products for retail display.

Why is tertiary packaging important?

It protects products during transportation and reduces damage in bulk shipping.

Which packaging is best for dry foods?

Multi-layer laminated pouches with moisture barriers and resealable features work best.

Is PET safe for beverages?

Yes, food-grade PET is widely used and approved for beverage packaging.

What packaging increases shelf life?

Vacuum packaging, Modified Atmosphere Packaging (MAP), and multi-layer barrier films.

What are the 3 levels of food packaging?

Primary (direct contact), Secondary (grouping), and Tertiary (transport).

What is the best packaging material for snacks?

Metalized laminated pouches with nitrogen flushing.

Which beverage packaging is most sustainable?

Glass and aluminum are highly recyclable; rPET is also a growing sustainable option.

How do I choose packaging for my food business?

Consider shelf life, moisture sensitivity, transportation needs, regulations, and branding.

Conclusion

Understanding the difference between primary, secondary, and tertiary food packaging helps businesses improve product safety, reduce losses, and enhance branding. From moisture-resistant pouches for grains to PET and glass solutions for beverages, selecting the right packaging depends on product category, logistics, and sustainability goals. Investing in the right packaging strategy not only protects your food products – it strengthens your brand and boosts customer trust. If you are looking to buy packaging materials and solutions in bulk, Moglix Packaging is the one stop designation to procure them effortlessly. We ensure the purchase of packaging materials at the most competitive prices with customization an dpriniting options.

Top 10 Best Double-Sided Tape Manufacturing Companies In India 2026: Types, Prices, And Features

Top 10 Best Double-Sided Tape Manufacturing Companies In India 2026: Types, Prices, And Features

Double-sided tapes are widely used across industries such as construction, automotive, electronics, packaging, signage, and home décor. These tapes have adhesive on both sides, allowing two surfaces to bond without visible fasteners. They provide strong adhesion, durability, and clean finishing. In India, the demand for double-sided tape is growing rapidly due to increased industrial production, infrastructure development, and DIY usage. Businesses and industries looking to buy adhesive tapes in bulk, whether single-sided or double-sided, can simply procure them at Moglix. We provide you with a wide range of adhesive tapes based on your project requirements from various reputed brands and manufacturers at competitive prices.

However, for your easy understanding and comprehensive buying experience, this guide covers the top 10 manufacturers, types, price ranges, and features of double-sided tapes in India.

What Is Double-Sided Tape?

Double-sided tape is a pressure-sensitive adhesive tape coated on both sides, designed to stick two surfaces together permanently or temporarily. It is commonly used for mounting, bonding, decorating, laminating, and industrial applications. These tapes can be made from foam, acrylic, rubber, or polyester backing, depending on their strength and application.

Detailed Overview of the Best Double-Sided Tape Manufacturers In India

Based on Recent data, peer reviews, and covering a wide range of products, we have curated a list of the best double-sided tape manufacturing companies. You can go through them once and find the right product based on your project requirement in bulk.

1. 3M India Ltd.

3M India is one of the most trusted names in adhesive technology worldwide. The company is known for producing premium-quality double-sided tapes with advanced bonding strength and durability. Their tapes are widely used in automotive assembly, construction panels, electronics mounting, and signage applications. 3M focuses heavily on innovation, offering heat-resistant, waterproof, and long-lasting adhesive solutions.

Key Pointers:

- Global brand reputation

- Very High Bond (VHB) technology

- Long service life

- Ideal for industrial use

2. Tesa Tapes India Pvt. Ltd.

Tesa is a German-based adhesive company with a strong presence in India. It specializes in high-performance industrial tapes designed for precision bonding and durability. Their double-sided tapes are known for strong adhesion, UV resistance, and weatherproof performance, making them suitable for automotive, electronics, and printing industries.

Key Pointers:

- High-performance adhesive solutions

- UV and weather resistance

- Industrial-grade quality

- Premium pricing segment

3. Wonder Polymers Pvt. Ltd.

Wonder Polymers is a leading Indian manufacturer known for affordable and reliable adhesive tape solutions. The company produces foam, acrylic, and tissue double-sided tapes that are widely used in construction, interior decoration, and packaging industries. Their products are popular for cost-effectiveness and customization options.

Key Pointers:

- Budget-friendly products

- Custom thickness availability

- Strong local distribution

- Suitable for commercial use

4. Bagla Group

Bagla Group has built a strong reputation in India’s adhesive industry with a wide variety of tape solutions. Their double-sided tapes offer excellent bonding strength and durability for industrial and export markets. The company focuses on high production capacity and consistent quality standards.

Key Pointers:

- Wide product range

- Export-quality manufacturing

- Strong adhesive strength

- Bulk supply capability

5. Lohmann India Pvt. Ltd.

Lohmann is a global adhesive specialist known for advanced bonding technologies. Its double-sided tapes are designed for high-precision industrial applications such as automotive interiors, electronics, and solar panel assembly. The company emphasizes innovation, research, and customized adhesive solutions.

Key Pointers:

- Advanced bonding technology

- Premium industrial applications

- Custom product solutions

- High durability standards

6. Advance Tapes India

Advance Tapes India is a well-known manufacturer offering a wide range of double-sided foam and tissue tapes. The company focuses on providing reliable adhesion solutions for construction, HVAC systems, and packaging industries. Their products are recognized for affordability and consistent quality.

Key Pointers:

- Competitive pricing

- Reliable bonding strength

- Strong domestic market presence

- Suitable for medium-duty use

7. Twin Tech India

Twin Tech India produces high-quality polyester and cloth double-sided tapes designed for industrial bonding needs. Their products are widely used in electronics, insulation, and manufacturing sectors. The company also offers customization in size, thickness, and adhesive strength.

Key Pointers:

- Custom manufacturing options

- Strong adhesive performance

- Industrial-grade materials

- Reliable bulk supply

8. R.K. Industries

R.K. Industries is a trusted domestic manufacturer providing durable double-sided tapes for construction, HVAC installation, and mounting applications. Their foam and tissue tapes are known for long-lasting adhesion and consistent performance.

Key Pointers:

- Durable foam tapes

- Strong market presence in North India

- Cost-effective solutions

- Good for mounting applications

9. Saroi Tapes

Saroi Tapes specializes in heavy-duty industrial double-sided tapes designed for high-strength bonding. The company supplies both domestic and international markets and is known for delivering reliable adhesive performance even in extreme conditions.

Key Pointers:

- Heavy-duty industrial tapes

- Export-quality products

- High load-bearing strength

- Weather-resistant adhesives

10. DS Enterprises

DS Enterprises is known for producing innovative nano and reusable double-sided tapes. Their products are popular in household and decorative applications due to their washable and residue-free adhesive properties.

Key Pointers:

- Nano reusable tape technology

- Waterproof adhesive

- Ideal for home use

- Affordable pricing

Types Of Double-Sided Tapes In India

1. Tissue Double-Sided Tape

- Thin and flexible

- Ideal for paper, printing, and packaging

2. Foam Double-Sided Tape

- Thick and shock-absorbing

- Used in mounting and signage

3. Acrylic Double-Sided Tape

- High durability

- Suitable for automotive and construction

4. PET Double-Sided Tape

- High temperature resistance

- Used in electronics

5. Nano Gel Double-Sided Tape

- Washable and reusable

- Popular for home applications

Price Range Of Double-Sided Tape In India

The price depends on material, thickness, and brand.

Typical Price Range:

- Basic tissue tape: ₹70 – ₹200

- Foam mounting tape: ₹80 – ₹400

- Industrial acrylic tape: ₹300 – ₹1000

- Nano reusable tape: ₹150 – ₹600

Some commercial listings show products priced between ₹70 and ₹900, depending on quality and size.

Look at the Key Features Of Double-Sided Tapes

1. Strong Adhesion

They offer excellent bonding strength for multiple surfaces.

2. Clean Finish

Since the tape stays between objects, it creates a neat appearance.

3. Heat & Moisture Resistance

Many tapes withstand high temperatures and humidity.

4. Versatility

Used for plastic, metal, wood, fabric, and glass bonding.

5. Easy Application

Simple to cut, apply, and remove without damage.

What are the Applications Of Double-Sided Tapes?

Industrial Uses:

- Automotive assembly

- Electronics mounting

- Signboard installation

Commercial Uses:

- Packaging and printing

- Furniture fixing

- Decoration work

Household Uses:

- Wall mounting

- Cable management

- Carpet fixing

How To Choose The Best Double-Sided Tape

Consider these factors:

- Surface type (smooth or rough)

- Load capacity

- Temperature resistance

- Thickness requirement

- Indoor or outdoor usage

Conclusion

Double-sided tapes are essential bonding solutions across industries and households. India has several reliable manufacturers offering high-quality, durable, and affordable adhesive tapes for multiple applications. From global brands like 3M and Tesa to local manufacturers like Wonder Polymers and Saroi Tapes, buyers can choose based on performance, price, and application needs. If you are also looking to buy double-sided tape or any other adhesive tapes in bulk, then Moglix is the one-stop destination to procure them effortlessly.

Top 10 Glass Bottle Manufacturers In India 2026: Wholesale Prices, Types, And Features

Top 10 Glass Bottle Manufacturers In India 2026: Wholesale Prices, Types, And Features

Glass bottles play a crucial role in packaging industries such as beverages, pharmaceuticals, cosmetics, food processing, and chemicals. Due to their eco-friendly nature, durability, and premium appearance, the demand for glass bottles in India continues to grow rapidly. In fact, the Indian glass bottle market is projected to grow strongly with rising demand for sustainable packaging solutions. If you are looking to buy glass bottles in bulk, then Moglix is the one destination to procure them effortlessly. We fulfill the bulk purchase of glass bottles at wholesale prices.

In this guide, we will explore the Top 10 glass bottle manufacturers in India, along with wholesale prices, types, and key features.

Overview of the Glass Bottle Industry in India

India is one of the largest producers of glass packaging materials. The industry is valued at billions of dollars and is expected to grow significantly due to demand from the beverage, pharmaceutical, and FMCG sectors.

Key growth drivers include:

- Increasing preference for recyclable packaging

- Rising consumption of packaged beverages

- Growth of pharmaceutical manufacturing

- Export demand for premium glass packaging

Check Out The Top 10 Glass Bottle Manufacturers In India?

Base don latest information, peer reviews, and budget fiendly option an dquality products, we have curated a list of the top 10 glass bottle manufacturers in India. Have a glance at them and choose based on your requirement.

1. Hindusthan National Glass & Industries Ltd.

One of India’s oldest and largest glass container manufacturers, HNG produces bottles for beverages, pharmaceuticals, and the food industry. The company has multiple manufacturing plants and supplies to major global brands.

Specialties:

- High production capacity

- Amber and soda-lime glass

- Bulk supply capabilities

2. AGI Glaspac

A leading manufacturer of flint and colored glass bottles, AGI serves industries such as liquor, pharma, and food packaging.

Key Features:

- Automated production technology

- Sustainable manufacturing

- Custom bottle design solutions

3. PGP Glass Private Limited

A premium glass packaging manufacturer exporting to more than 50 countries. Known for high-end cosmetic and pharmaceutical bottles.

Strengths:

- Luxury packaging designs

- Global export presence

- Advanced manufacturing plants

4. Haldyn Glass Limited

A reliable manufacturer producing affordable glass bottles for food, beverages, and pharma sectors.

Highlights:

- Cost-effective solutions

- ISO-certified quality

- High clarity glass

5. Piramal Glass Pvt. Ltd.

A global leader in cosmetic and perfume glass packaging.

Key Features:

- International quality standards

- Custom decoration options

- Premium bottle finishing

6. Borosil Limited

A well-known Indian glass manufacturer specializing in laboratory glassware and premium containers.

Strengths:

- Global presence

- High-quality glass production

- Durable and heat-resistant glass

7. Ajanta Bottle Private Limited

A trusted supplier of bulk glass bottles for FMCG, cosmetics, and pharmaceutical industries.

Features:

- Large MOQ supply

- Standard design catalog

- Affordable pricing

8. Empire Industries Limited

Produces a wide range of food, beverage, and chemical glass bottles.

Key Highlights:

- Strong industrial reputation

- Bulk manufacturing capacity

9. Pragati Glass Private Limited

Known for manufacturing durable glass packaging solutions for the food and beverage sector.

Strengths:

- Customized bottle designs

- Reliable supply chain

10. Eagle Glass Deco Private Limited

Specializes in decorative glass bottles used for cosmetics, perfumes, and premium packaging.

Features:

- Attractive designs

- High-quality finishing

Indicative Wholesale Prices of Glass Bottles in India for 2026

Wholesale prices vary based on size, design, and quantity.

Typical Price Range

- Mini glass bottles: ₹50 – ₹150

- 250 ml bottles: ₹80 – ₹200

- 1-liter bottles: ₹150 – ₹300

- Decorative bottles: ₹200 – ₹600

Some specialized glass bottles can cost as low as ₹12–₹25 per piece in bulk orders.

What are the Types of Glass Bottles?

1. Beverage Bottles

Used for water, juices, and soft drinks. Usually feature screw caps and durable glass.

2. Pharmaceutical Bottles

Amber glass protects medicines from UV light.

3. Cosmetic Bottles

Premium designs are used for perfumes and beauty products.

4. Food Storage Bottles

Used for sauces, pickles, and jams.

5. Decorative Glass Bottles

Mainly used for gifting and home décor.

Understand the Key Features of Glass Bottles before procuring

Eco-Friendly

Glass is fully recyclable and environmentally sustainable.

Durable and Reusable

Glass bottles can be reused multiple times.

Chemical Resistance

They do not react with liquids stored inside.

Premium Appearance

Glass packaging enhances brand value.

Conclusion

India is home to some of the world’s leading glass bottle manufacturers offering high-quality packaging solutions at competitive prices. Companies like HNG, AGI Glaspac, and PGP Glass dominate the industry with advanced technology and global supply chains. As sustainability becomes a priority, the demand for eco-friendly glass bottles will continue to grow, making this industry highly promising in 2026 and beyond. Businesses and industries looking to buy glass bottles in bulk, then Moglix Business is the right platform for them to purchase them effortlessly. We ensure the procurement of glass bottles from various repeat manufacturers and sources.

Top 10 Biodegradable Plastic Bags Manufacturers In India 2026: Latest Ranking, Prices, And Features To Look For

Top 10 Biodegradable Plastic Bags Manufacturers In India 2026: Latest Ranking, Prices, And Features To Look For

India is rapidly shifting toward eco-friendly packaging due to strict bans on single-use plastic and rising environmental awareness. Biodegradable plastic bags, often made from plant starch, compostable polymers, and water-soluble materials, are becoming essential for retail, e-commerce, and industrial use. In 2026, the Indian market for biodegradable plastic bags is expanding quickly, offering certified compostable products, custom printing options, and competitive bulk pricing. Businesses and industries looking to buy compostable and Biodegradable plastic bags in bulk can simply procure them at Moglix from various manufacturers and suppliers at the best prices. We ensure the procurement of compostable plastic bags at the most effective prices with a hassle-free purchase process.

However, for a comprehensive purchase, this guide covers the Top 10 biodegradable plastic bag manufacturers in India, along with pricing trends, key features, and buying tips.

What Are Biodegradable Plastic Bags?

Biodegradable plastic bags are eco-friendly alternatives to conventional plastic. They are designed to break down naturally through microorganisms, leaving no harmful residues.

These bags are typically made from:

- Corn starch and plant extracts

- Polyvinyl alcohol (PVA)

- Vegetable oil derivatives

- Compostable polymer blends

Check Out the Top 10 Biodegradable Plastic Bag Manufacturers in India 2026

By analyzing the various suppliers and manufacturers, their production, quality of products, peer reviews, and supply chain efficiency, we have collected the latest data and curated the list of top 10 compostable and Biodegradable Plastic Bag Manufacturers in India 2026.

1. BioBaggy

Ranking: #1 eco packaging supplier (2026)

Key Features

- ISO-certified compostable bags

- Carry bags, garbage bags, food-grade pouches

- Heavy-duty and leak-proof design

- Custom printing available

Price Range

- ₹125–₹130 per kg wholesale

BioBaggy’s products meet international compostability standards and decompose within about 180 days under composting conditions.

2. Green Tech Bio Products (GreenPlast)

Ranking: Best innovation technology

Key Features

- Water-soluble biodegradable bags

- Made from starch and PVA

- Non-toxic and eco-safe

- Strong elasticity like plastic

This company is known for manufacturing the raw biodegradable pellets in India, helping reduce production costs.

3. Biouva

Ranking: Best for affordable bulk supply

Key Features

- Certified compostable bags

- Transparent, grocery, and mailer bags

- Custom printing options

Price Range

- ₹120–₹130 per kg

- ₹3–₹7 per bag (small sizes)

4. Naturoplast India

Ranking: Best for customization

Key Features

- BIS-approved compostable bags

- Multiple sizes and microns

- High weight-carrying capacity

- Custom color and printing

The company offers carry bags that can hold up to 10 kg weight depending on thickness.

5. Navika Industries

Ranking: Best for certified compliance

Key Features

- IS/ISO-certified products

- Made from plant-based raw materials

- Suitable for retail, agriculture, and industrial use

- Fully compostable design

6. Scarbon

Ranking: Best sustainable sourcing platform

Key Features

- CPCB and ISO-tested products

- Large supply capacity

- Nationwide vendor network

- Certified quality audits

7. Easy Flux Polymers

Ranking: Best for large-scale manufacturing

Key Features

- 100% compostable carry bags

- Garbage bags and envelopes

- Eco-friendly polymer technology

8. Biogreen Biotech

Ranking: Best eco biotech innovation

Key Features

- Fully compostable materials

- Wide product range

- International supply capability

9. Desco Medical India

Ranking: Best for healthcare biodegradable bags

Key Features

- Biomedical waste bags

- Water-soluble and oxo-biodegradable options

- Industrial applications

10. Pepcom India

Ranking: Emerging sustainable packaging brand

Key Features

- Compostable packaging solutions

- Food-safe certified materials

- Strong environmental impact focus

What are the Latest Price Trends of Biodegradable Bags in India (2026)

Typical market prices include:

| Product Type | Average Price |

| Carry bags | ₹150–₹300 per kg |

| Compostable grocery bags | ₹250–₹310 per kg |

| PLA biodegradable bags | Around ₹300 per pack |

| Small compostable bags | ₹3–₹7 per piece |

Prices vary based on thickness, size, certification, and bulk quantity.

Understand the Key Features to Look For Before Buying

1. Certification Standards

Always check for:

- ISO 17088 compostability certification

- CPCB approval

- BIS certification

These confirm genuine biodegradability.

2. Material Type

Choose based on application:

- Corn-starch bags – retail use

- PVA water-soluble – medical use

- PLA compostable – food packaging

3. Strength and Thickness

Higher micron levels provide:

- Better durability

- Higher load capacity

- Tear resistance

4. Decomposition Time

Look for bags that decompose within:

- 90–180 days under compost conditions

5. Customization Options

Important for businesses:

- Printing branding logos

- Custom sizes

- Color choices

Applications of Biodegradable Plastic Bags

These eco bags are widely used in:

- Retail shopping bags

- Garbage liners

- Food packaging

- E-commerce courier bags

- Agriculture and nursery bags

Conclusion

Biodegradable plastic bags are no longer niche products; they are becoming the new standard in India’s packaging industry. From affordable bulk suppliers like Biouva to advanced innovators like GreenPlast, the market offers solutions for every industry. When choosing a manufacturer, focus on certification, durability, pricing, and customization options to ensure you get truly eco-friendly and cost-effective products. If you are looking to buy Biodegradable Plastic Bags, then Moglix Business is the right platform to procure them effortlessly. We ensure the procurement of compostable and biodegradable plastic bags from top brands and manufacturers at the most competitive prices.

Top 10 Garbage Bags Manufacturers In India 2026: Small, Medium, And Large Garbage Bags With Prices And Features

Top 10 Garbage Bags Manufacturers In India 2026: Small, Medium, And Large Garbage Bags With Prices And Features

Garbage bags, whether referred to as dustbin bags, trash bags, bin liners, or garbage sack liners, are essential for hygienic and efficient waste management in homes, offices, industries, hospitals, and public spaces. In India’s growing market for sustainable and everyday utility products, many manufacturers now offer a broad range of products, including biodegradable garbage bags, high-strength plastic bags, and eco-friendly trash bags of various sizes.

Businesses, industries, and retailers seek for top quality trash and garbage bags based on their requirements. If you are also looking to buy garbage bags in bulk, then Moglix is the one-stop destination to procure them efficiently. We offer you a wide range of dustbin bags to trash bags of different sizes, with a customized option to fulfill every specific requirement. Therefore, this blog dives into the top 10 garbage bag manufacturers in India (2026), along with their popular products, key features, approximate price ranges, and what makes them stand out.

What Are The Various Types Of Garbage Bags?

Knowing every specific type of garbage bag is important to find the right product based on the project requirement.

- Standard Plastic Garbage Bags

Made from LDPE or HDPE material, these are the most commonly used dustbin bags for homes, offices, and commercial spaces. They are cost-effective, lightweight, and suitable for dry and mixed waste. - Biodegradable Garbage Bags

These bags are manufactured using plant-based or compostable materials and are designed to decompose faster than regular plastic. Biodegradable garbage bags are ideal for eco-conscious households and organizations focusing on sustainable waste management. - Compostable Trash Bags

A sub-category of biodegradable bags, compostable trash bags break down completely into natural elements under composting conditions, making them suitable for organic and wet waste disposal. - Scented Garbage Bags

These trash bags come with fragrance additives to help control unpleasant odors, making them suitable for indoor bins and food waste disposal areas. - Recycled Plastic Garbage Bags

Manufactured using post-consumer recycled plastic, these bags help reduce plastic waste while offering reliable strength for everyday garbage collection. - Color-Coded Garbage Bags

Used for waste segregation, different colors indicate dry waste, wet waste, biomedical waste, or hazardous waste, commonly used in hospitals and municipalities.

Check Out The List Of The Top 10 Garbage Bags In India 2026

Based on peer reviews, quality of products, extensive catalog, and overall sales, we have curated the list of the top 10 trash garbage bags manufacturers you can opt for. Let’s have a quick look at them:

1. Greendot Biopak Pvt. Ltd. – Eco & Compostable Garbage Bags

A leading Indian manufacturer specializing in biodegradable garbage bags that are eco-friendly alternatives to traditional plastic bags. Their products are made from plant-based materials and designed to break down naturally over time.

Key Features:

- Compostable and biodegradable materials (plant-based)

- Leak-proof, tear-resistant, and durable

- Suitable for wet and dry waste

- Ideal for homes, offices, hospitality, and public bins

- Multi-size options available

Typical Price: Rs. 180–Rs. 350/kg depending on size/material

Best For: Environment-friendly disposal, green waste bins

2. Sri Krishna Polymers – Comprehensive Garbage Bag Range

A well-established Indian manufacturer offering a wide portfolio of garbage bags, including biodegradable trash bags, plastic dustbin bags, eco options, and clinical waste bags.

Key Features:

- HDPE and LDPE options (plastic & biodegradable)

- Custom sizes and thicknesses

- Dustbin covers for small to large bins

- Disposable, eco, biohazard, and compostable bags

Typical Price: Rs. 80–Rs. 200/kg (varies by product type)

Best For: General household waste, commercial trash bags

3. Murth – CPCB-Certified Biodegradable Dustbin Bags

An Indian brand known for CPCB-certified biodegradable garbage bags made from plant-based biopolymers, suited for households and commercial usage.

Key Features:

- 100% compostable and biodegradable

- CPCB & IS/ISO standards compliance

- Leak-proof and tear-resistant

- Varied sizes, including small, medium, and large

- Breaks down in 60–180 days

Typical Price Range: Rs. 250–Rs. 360/kg

Best For: Eco-conscious users and institutional waste management

4. Arihant Industries India – Dustbin & Trash Bag Manufacturer

A manufacturer offering standard and biodegradable garbage bags, including heavy-duty trash bags and dustbin liners.

Key Features:

- Standard plastic garbage bags (various sizes)

- Biodegradable options available

- Heavy-duty and biohazard variants

- On-roll and flat pack formats

Typical Price: Rs. 15–Rs. 30 per piece (varies by type & size)

Best For: Bulk needs, industrial waste, and daily dustbin use

5. Allied Propack Pvt. Ltd. – Recycled & Dustbin Bags

Listed among India’s reliable recycled garbage bag manufacturers, offering various sustainable and recycled trash bag solutions.

Key Features:

- Recycled plastic bags mitigate environmental impact

- Variety of sizes and capacities

- Suitable for everyday waste disposal

Typical Price: Competitive (varies by bulk orders)

Best For: Eco-friendly recycled options and budget buyers

6. Valor Industries – Recycled & Garbage Bag Supplier

Part of the top recycled trash bags suppliers in India, with a range of dustbin bags produced from recycled plastics.

Key Features:

- Recycled plastic waste bag range

- Strong and tear-resistant

- Available to bulk customers

Typical Price: Varies by material and weight

Best For: Commercial, household, and eco-conscious customers

7. Velox Hygiene Products LLP – Waste Bags

Another notable manufacturer of recycled and biodegradable garbage bags is especially for commercial and household waste collection.

Key Features:

- Focus on hygiene and durable performance

- Sizes from small household liners to large trash bags

- Eco-oriented recycled products

Typical Price: Market competitive

Best For: Businesses and institutional waste management

8. Eco365 – Compostable Garbage Bag Brand

A popular seller of 100% compostable and biodegradable trash bags in India, made from plant extracts and designed to meet environmental standards.

Key Features:

- Certified biodegradable, non-plastic bags

- Compostable in natural conditions

- Available in small to medium pack sizes

Typical Price: Rs. 190–Rs. 300 per pack (size dependent)

Best For: Home composters and eco-focused households

9. Shakthi Enterprises – Durable Biodegradable Garbage Bags

Manufacturers focused on producing biodegradable and eco-friendly dustbin bags that are strong and tear-resistant.

Key Features:

- Biodegradable materials

- Leak-proof and tough design

- Multiple size formats

Typical Price: Varies (depending on size and material grade)

Best For: Everyday and medium–heavy use waste disposal

10. Clean India Biodegradable Garbage Bag Range

Although not a single manufacturer brand, Clean India’s biodegradable trash bags are widely used eco-bags from various suppliers across India, notable for affordability and growth in demand.

Key Features:

- Biodegradable material

- Leak-proof and durable

- Medium to large dustbin sizes

- Affordable price

Typical Price: Rs. 36 for 15 bags (medium)

Best For: Daily home and light commercial use

Quick look at the Garbage Bags Buying Guide (2026)

Based on Sizes & Uses

- Small Garbage Bags (Drawstring/Small Dustbin Bags): Best for bathroom bins, bedrooms – typically 8–15 L capacity.

- Medium Trash Bags: Ideal for kitchen waste or office bins – around 20–35 L.

- Large Garbage Bags: For outdoor bins, commercial kitchens, and event clean-up – 50–90+ L.

Biodegradable vs. Traditional Plastic Bags

- Traditional Plastic Bags: Cheaper, stronger, but take hundreds of years to degrade.

- Biodegradable Garbage Bags: Break down faster under proper conditions; much better for the environment.

- Important to choose CPCB/ISO-certified compostable bags for proper waste segregation and compliance.

Key Features to Consider

Leak-proof & Tear-resistant: Prevent messy spills.

Drawstring or Tie Closure: Helps secure waste easily.

Capacity & Thickness: Thick gauge for heavy waste.

Eco Certifications: CPCB/ISO standards ensure actual biodegradability.

Final Thoughts

Whether you’re stocking up for home kitchens, corporate offices, industrial facilities, hospitals, or public waste management programs, India’s garbage bag manufacturing ecosystem in 2026 offers durable, eco-friendly, and affordable options. Choosing the right brand, from everyday dustbin bags to advanced biodegradable garbage bags, not only simplifies waste disposal but also supports cleaner cities and sustainable living.

However, if you are looking for bulk procurement of garbage bags from top and trustworthy suppliers and manufacturers, Packaging Moglix is the one-stop online platform for effective and hassle-free purchase. You can easily raiase RFQ based on your requirement and get delivered over pan India.

Top 10 Paper Bag Manufacturers in India 2026: Types, Prices, And Features to Look For

Top 10 Paper Bag Manufacturers in India 2026: Types, Prices, And Features to Look For

The continuous focus on sustainability has evoked the usage of paper bags, becoming the priority for many businesses to utilize sustainable materials and replace plastic across various retail, gifting, e-commerce, and food services. Not only in India, but also the global organizations are spreading awareness to eliminate plastic, while focusing on sustainable materials like paper bags, to expand rapidly. Therefore, enterprises and businesses looking to procure kraft paper bags, white paper bags, custom paper bags, printed paper bags, small paper bags, brown paper bags, paper carrier bags, etc., can partner with Moglix and procure them seamlessly in bulk.

However, for your better understanding, we have provided you with a complete guide on the top 10 paper bag suppliers in India 2026. Let’s have a quick look at the complete list.

Importance of Paper Bags in 2026

The importance of Paper bags cannot be overlooked in recent period. They are known for

- Best eco-friendly and biodegradable packaging solution

- Provide decent durability with a stylish look and available in printed option

- Can be utilized across various sectors, from the grocery business to luxury retail.

- Cost-efficient with a bulk pricing option

Types of Paper Bags Common in India

Here are the main types you’ll find:

| Type | Description | Typical Price Range (India) |

| Kraft Paper Bags | Strong, recycled, everyday use | ₹10–₹30 |

| Brown Paper Bags | Natural look, sturdy | ₹15–₹35 |

| Printed Bags | Custom brand logos and designs | ₹20–₹50 |

| Shopping Bags | Reinforced handles for retail | ₹25–₹60 |

| Luxury Paper Bags | Premium finish, gifting | ₹50–₹150 |

Top 10 Paper Bag Manufacturers in India (2026)

We have curated the list of top 10 paper bag manufacturers in India for 2026 based on recent developments, product range, peer reviews, customization option and reputation.

OLIVIA INTERNATIONAL

One of the most reputed and well-known brands for providing value pricing and quality paper kraft bags. It is an excellent choice for beginners, startups, or small retailers. They offer a complete range of paper bags with customization options and a low minimum order quantity.

Best for: Small businesses, Low pricing, Standard retail bags

CONIFER HANDMADES

One of the most highly rated paper bag suppliers, offering premium quality and a wide range of sustainable bags at the best prices. The strong and positive reviews over time showcases theur experience and powerful brand in packaging solution providers.

Best for: Premium gifting bags, Custom print, Boutique brands

FLYMAX EXIM

The brand mostly focuses on designing durable, attractive, and FSC-certified bags. They have been setting the trends with amazing, strong, and appealing designs in their paper bags.

Best for: Branded retail packaging, Recyclable bags

TAJ PAPER UDYOG

It is also one of the most standard brands offering the best and most robust custom paper bags. What makes them outstanding is the customization and printing options.

Best for: Custom projects, Mid-tier orders

BIZCOVERINDIA.COM LLP

One of the most efficient and verified paper bag suppliers with a humongous production space. The band ofes a larger projects and bulk contracts at a single time.

Best for: Bulk orders, B2B clients

ECOREV

The brand offers effective, recyclable, and eco-friendly paper bags with amazing and robust quality. It offers a wide range of products for sustainability and quality at the top.

Best for: Eco-conscious brands, Mid-sized orders

VISION GLOBAL EXPORT

Reliable manufacturer offering multi-size bags with custom printing at competitive prices. Good option for retailers and small exporters.

Best for: Retail & export orders

FARHANCRYSTAL

Known for biodegradable, food-grade bags, especially for restaurants and QSR chains. Offers competitive price points.

Best for: Food & beverage packaging

Dutta Enterprise

A seasoned manufacturer with experience in biodegradable and custom printed bags, including duplex and jewelry bags.

Best for: Custom orders, Diverse bag types

Pilani Udyog

Operating since the ’90s, this company has made a wide range of paper bags and accessories, including SOS bags and envelopes. Good logistics support.

Best for: Diverse product range, Large B2B clients

Paper bag indicative Pricing in 2026

Pricing depends on:

- Material quality (GSM)

- Handles (twisted rope, ribbon, reinforced)

- Print (single color vs CMYK/Pantone)

- Order quantity & customization

Typical wholesale ranges in India:

- Basic Kraft (no print): ₹2.50–₹6 per piece

- Printed Paper Bags: ₹6–₹15 per piece

- Laminated/Gift Bags: ₹10–₹30+ per piece (premium)

Key Features to Look for Before Buying Paper Bags

Choosing the right manufacturer is more than just pricing. Here’s what to consider:

- Material Quality: Never compromise on the quality of materials used in the manufacturing of paper bags. You can look for high GSM kraft and recycled paper for better strength and quality.

- Handle & Usability: Check the design and features like paper nag with handles for better usability. It offers comfort and better load support.

- Print Quality: If you are focusing on better brand visibility, then do not compromise on the print quality on paper bags. Always choose brands that offer high-resolution CMYK printing and logo design with other customization options.

- Eco Certification: Prioritize the FSC, ISO 9001, or sustainability credentials that show credible practices.

- MOQ & Lead Time: Check minimum order quantity and delivery timelines before ordering.

Conclusion

Paper bags are known as a reliable packaging solution for sustainability and branding. No matter whether you are a small business, industry, or enterprise, paper bags have spread their horizons in every sector. In 2026, the demand is rising, and many sectors are opting for paper kraft bags to deliver powerful messages, braiding, and eco-friendly options towards the growth of business and the environment, too. However, if you are looking for a one-stop destination and online platform to buy paper bags at the most affordable price, you can partner with Moglix Packaging.

How Packaging is Important in E-Commerce Marketing?

How Packaging is Important in E-Commerce Marketing?

In today’s highly competitive digital marketplace, packaging has become a powerful marketing tool for e-commerce businesses. With millions of online sellers offering similar products, packaging is no longer just about protection—it plays a crucial role in branding, customer experience, logistics, and customer retention. Unlike physical retail stores, e-commerce brands have only one physical touchpoint with customers: the product packaging. This makes packaging a vital component of an e-commerce marketing strategy. If you are looking for a complete packaging solution, then you can opt for the Moglix packaging. We provide you with overall packaging material as per your product and project requirements.

This article explores why packaging is important in e-commerce marketing, its benefits, types, trends, and how businesses can use packaging to drive growth.

Understand The Importance Of Packaging In Marketing: 10 Points To Remember

Based on the overall understanding, we have curated 10 points for the importance of packaging in overall e-commerce marketing. Let’s drive through them:

1. First Impression and Brand Identity

Packaging creates the first physical impression of an online brand. Since customers cannot touch or see the product before purchase, the unboxing experience becomes the moment when expectations are met—or broken.

- Custom-designed boxes, logos, colors, and typography help establish brand identity

- Premium packaging builds trust and conveys quality

- Consistent packaging improves brand recall and recognition

A well-designed e-commerce package makes customers feel they made the right purchasing decision and strengthens brand loyalty.

2. Packaging as a Marketing Tool

Packaging acts as silent advertising for e-commerce brands. From branded boxes to inserts and QR codes, packaging continues marketing even after delivery.

Marketing benefits of e-commerce packaging include:

- Promoting brand values and messaging

- Encouraging social media sharing (unboxing videos)

- Cross-selling and upselling through flyers or discount coupons

- Driving repeat purchases with loyalty messages

In the age of Instagram and YouTube, visually appealing packaging can go viral, giving brands free marketing exposure.

3. Enhancing Customer Experience (Unboxing Experience)

The unboxing experience has become a key factor in customer satisfaction. A thoughtfully packed product can turn a one-time buyer into a repeat customer.

- Neatly packed items increase perceived product value

- Protective inserts reduce damage and return

- Personalized notes create an emotional connection

A positive unboxing experience improves customer reviews, ratings, and word-of-mouth marketing.

4. Product Protection and Reduced Returns

One of the most important roles of packaging in e-commerce is protecting products during transit. Poor packaging leads to damaged goods, unhappy customers, and high return rates.

Effective packaging:

- Prevents breakage, leakage, and wear

- Reduces logistics and replacement costs

- Ensures products reach customers in perfect condition

Strong packaging improves operational efficiency while protecting brand reputation.

5. Cost Efficiency and Logistics Optimization

Smart packaging design helps e-commerce businesses optimize shipping costs and storage.

- Right-sized packaging reduces shipping weight and dimensional charges

- Stackable designs improve warehouse efficiency

- Lightweight materials lower transportation costs

Well-planned packaging directly impacts profit margins by reducing unnecessary expenses.

6. Sustainable Packaging Builds Brand Trust

Eco-friendly packaging has become a major differentiator in e-commerce marketing. Modern consumers prefer brands that demonstrate environmental responsibility.

Benefits of sustainable packaging:

- Builds positive brand image

- Appeals to eco-conscious customers

- Reduces environmental footprint

- Meets regulatory and marketplace guidelines

Materials like recyclable cardboard, paper fillers, biodegradable plastics, and minimal packaging designs help brands align with sustainability goals.

7. Custom Packaging Improves Brand Recognition

Custom packaging is essential for standing out in a crowded e-commerce marketplace.

Examples include:

- Branded corrugated boxes

- Custom-printed poly mailers

- Logo-printed tapes and labels

Custom packaging reinforces branding and increases customer recall, making it easier for buyers to recognize the brand in future purchases.

8. Packaging Influences Customer Reviews and Ratings

Customer feedback in e-commerce is heavily influenced by packaging quality.

Good packaging leads to:

- Positive product reviews

- Higher seller ratings

- Fewer complaints and disputes

Poor packaging, even with a great product, can result in negative reviews and lower conversion rates.

9. Packaging and Personalization in E-Commerce

Personalized packaging adds a human touch to online shopping.

Examples of personalization:

- Customer name on packaging

- Thank-you cards

- Occasion-based packaging (festive, gifting, birthdays)

Personalized packaging enhances customer loyalty and emotional connection with the brand.

10. Compliance and Information Transparency

E-commerce packaging must also meet legal and informational requirements.

Important information includes:

- Product details and usage instructions

- Manufacturing and expiry dates

- Barcodes and QR codes

- Return and contact information

Clear labeling builds transparency and increases customer confidence.

Types of Packaging Used in E-Commerce

Common e-commerce packaging types include:

- Corrugated cardboard boxes

- Poly mailers and courier bags

- Bubble wrap and air pillows

- Paper fillers and molded pulp

- Tamper-proof packaging

Choosing the right packaging depends on product type, size, fragility, and shipping distance.

Future Trends in E-Commerce Packaging

The future of e-commerce packaging focuses on innovation and sustainability.

Key trends include:

- Minimalist and right-sized packaging

- Smart packaging with QR codes and tracking

- Reusable and returnable packaging

- Plastic-free and compostable materials

Brands adopting these trends gain a competitive edge in modern e-commerce marketing.

Conclusion

Packaging is no longer just a protective layer; it is a powerful marketing asset in e-commerce. From branding and customer experience to logistics optimization and sustainability, packaging solution influences every stage of the e-commerce journey. Businesses that invest in smart, sustainable, and customer-centric packaging gain higher customer satisfaction, better brand visibility, and long-term growth. In the fast-evolving world of e-commerce marketing, great packaging is not an expense, it’s an investment.

Top 10 Corrugated Cardboard and Packing Box Manufacturers in India 2026: Types, Prices, and Features to Look For

Top 10 Corrugated Cardboard and Packing Box Manufacturers in India 2026: Types, Prices, and Features to Look For

The corrugated cardboard and packing box industry in India is vital to manufacturing, logistics, e-commerce, and retail sectors. With India’s packaging industry poised for strong growth, corrugated box demand continues to surge due to rising online shopping, industrial shipments, and sustainable packaging preferences. However, if you are looking to buy corrugated boxes in bulk at wholesale prices, then Moglix is the best platform to procure them. We offer you a wide range of packaging solutions at the most affordable prices.

This comprehensive blog covers the top 10 corrugated cardboard and packing box manufacturers in India in 2026, the types of corrugated boxes, price ranges, and key features to consider when choosing the right packaging partner.

What Are Corrugated Cardboard Boxes?

Corrugated cardboard boxes are made from layers of paperboard material: flat linerboards sandwiching a fluted, corrugated medium. This structure provides strength, cushioning, and protection for products in storage and transit. The number of paper layers (plies) and flute type determine the box’s strength and applications.

Top 10 Corrugated Cardboard & Packing Box Manufacturers in India (2026)

Here are the leading companies that stand out in quality, delivery, and range of packaging solutions:

1. TGI Packaging Pvt. Ltd.

One of India’s most established corrugated box manufacturers with decades of experience. Known for high-quality corrugated solutions and export capabilities, TGI produces thousands of tons of boxes annually with automated production facilities – ideal for large volumes and tailored designs.

2. Canpac Trends Pvt. Ltd.

A premium packaging company providing flexible packaging solutions, including corrugated boxes, folding cartons, and specialty products. Known for design expertise and sustainable materials.

3. Aaradhya Enterprise

A trusted name supplying corrugated packaging solutions across industries like food and beverage, pharma, electronics, and FMCG. Offers customized sizing and material options.

4. Hariwansh Packing Pvt. Ltd.

Offers a wide range of corrugated packaging products, including partition boxes, specialty designs, and custom prints. Known for providing end-to-end box solutions.

5. B&B Triplewall Containers Ltd.

Based in Bengaluru, this manufacturer delivers robust corrugated solutions for industrial, retail, and export sectors. Emphasis on eco-friendly packaging and quality standards.

6. Horizon Packs Pvt. Ltd.

Part of a leading packaging group, Horizon Packs offers corrugated boxes, cartons, and e-commerce packaging, with modern production lines serving pan-India clients.

7. Worth Peripherals Ltd.

Known for quality corrugated boards and boxes suitable for electronics, e-commerce, and FMCG sectors. Focuses on precision manufacturing and timely delivery.

8. Astron Packaging Ltd.

Offers a broad portfolio including printed and laminated corrugated packaging solutions. Strong presence in Gujarat and widely known for innovative box designs.

9. Marudhar Packaging

A growing manufacturer in Bangalore producing carton boxes, partitions, and printed corrugated packaging. Great choice for mid-sized businesses seeking quality and variety.

10. Ruchi Group (Rana Packers)

Based in South India, Ruchi Group supplies diverse corrugated box formats, including customized printing and branding services for regional markets.

Types of Corrugated Boxes & Typical Price Ranges in India

Below is a snapshot of common corrugated box types and typical price ranges in the Indian market:

| Box Type | Features | Typical Price Range |

| Single Wall (3-ply) | Lightweight, cost-effective | ₹8–₹15 per piece |

| Double Wall (5-ply) | Strong, durable for heavier items | ₹15–₹30 |

| Triple Wall (7-ply) | Maximum strength for industrial use | ₹30–₹50+ |

| Die-Cut Boxes | Custom shapes and designs | ₹20–₹40 |

| Foldable Boxes | Space-efficient & easy assembly | ₹10–₹25 |

| Heavy Duty / Industrial Boxes | Extra reinforced for machinery | ₹50–₹100+ |

Price varies based on size, ply levels, print quality, and customization. E-commerce sellers may pay more for printed branding and design features.

What Are The Key Features To Look For In Corrugated Boxes?

Choosing the right packing partner and material is essential for protecting your products and enhancing brand image. Here are key features to evaluate:

1. Material Quality

High-grade kraft paper and quality linerboards improve durability and resistance to crushing or moisture.

2. Ply & Strength Rating

Higher ply (e.g., 5 or 7 ply) increases strength and load-bearing capacity — important for heavy or fragile products.

3. Flute Type

Different flute sizes (A, B, C, E, etc.) affect cushioning and compression resistance. Choose based on shipment needs.

4. Customization & Print

Branding options like printed logos, barcode areas, and graphics strengthen brand visibility and customer experience.

5. Eco-Friendliness

Boxes made from recycled, recyclable, or sustainably sourced paper resonate with environmentally conscious customers and reduce disposal costs.

6. Size & Fit

Boxes should match product dimensions to minimize wasted space and reduce shipping costs while maximizing protection.

Corrugated Box Prices – What to Expect in 2026

In general:

- Small boxes (up to 30×20×20 cm): ₹15–₹70

- Medium boxes (30×30×30 to 50×40×40 cm): ₹30–₹100

- Large/Heavy-duty boxes: ₹70–₹200+

Prices depend on ply level, size, print quality, and any special coatings or reinforcement. Customized boxes typically cost more than standard plain brown boxes.

How to Choose the Right Manufacturer

To select the best corrugated box partner:

- Match your product size and weight to the correct ply and flute type.

- Ask for samples to test strength and print quality.

- Confirm minimum order quantities (MOQ) and lead times.

- Check for eco-friendly certifications if sustainability matters.

- Clarify delivery options and logistics support.

Final Thoughts

With India’s corrugated box market growing rapidly, choosing the right packaging partner can make a big difference in product safety, branding, and cost efficiency. By understanding the different box types, pricing, and the strengths of leading manufacturers, you can make informed decisions that support your business goals in 2026 and beyond. At the Moglix business, you can procure all types of packaging solutions at the most competitive prices. Check out our complete range of products and raise an RFQ accordingly.

Top 10 Packaging Companies in India 2026: Types, Prices And Features to Look For

Top 10 Packaging Companies in India 2026: Types, Prices And Features to Look For

As we are heading towards rapid industrial growth, the packaging process and transformation cannot be neglected in driving the success of industries. The emergence and significance of packaging materials play a pivotal role in the growth of e-commerce, FMCG, pharmaceutical, and global export opportunities. Even the progressive approach towards sustainable packaging has changed the business game. Therefore, every business and industry prioritizes the right type of packaging for products from various trusted and reputable brands. Keeping its importance at peak, we have collected the latest data for the top 10 packaging companies in India (2026), offering complete packaging solutions. However, if you are looking to buy packaging materials in bulk, then Moglix is the one-stop destination to procure them seamlessly. With this guide, you will be able to find the best packaging companies suitable for your products and analyze the pricing expectation, their offering, and key features that meet your packaging requirements.

Why Packaging Matters in 2026?

Packaging has become an influential, sustainable, and eye-appealing aspect for many industries, especially products like personal care, logistics, food and beverage, and pharmaceutical. Therefore, businesses want to stand out in every segment of their product efficiency, while focusing on below listed factors:

- Sustainability & recyclability

- Cost efficiency

- Durability & protection

- Compliance with food/ pharma safety standards

- Brand appeal & customization

We’ll cover both industry leaders and what makes them stand out in 2026.

Check Out the Complete List of Top 10 Packaging Companies In India (2026)

If you are also among those businesses and industries looking to procure the best packaging materials from reliable sources, then Moglix is the one-stop destination to avail them seamlessly. We have provided you with the list of the best packaging brands you can rely on.

1. Uflex Ltd.

One of the highly rated and renowned packaging companies, Uflex Ltd, offers a complete and flexible packaging solution around the globe. They ensure the procurement of packaging solutions like printed films, flexible pouches, and high-barrier laminates for food items, covering the entire FMCG and medical sectors. The price range of their packaging material falls between ₹6–₹12 per unit, and printed films range between ₹150–₹300 per kg. The company is well known for providing ISO and FDA-certified and sustainable packaging solutions.

2. Essel Propack Ltd. (EPL)

Essel Propack Ltd., also known as EPL, is a reputed brand based in Mumbai offering top-quality laminated tube packaging solutions. The company has been serving industries like cosmetics, pharmaceuticals, and personal care. The price of their packaging materials falls between ₹5–₹30 per piece, depending on the size and printing requirement.

3. TCPL Packaging Ltd.

TPCl is a leading manufacturer in the segment of packaging material, specializing in cartons and cardboard solutions. The company has been serving major sectors like liquor, FMCG, and pharmaceuticals, offering a wide range of packaging solutions. The folding or coagulated cartons cost between Rs 8 to 40 per piece, based on design and size requirement.

4. Jindal Poly Films Ltd.

Headquartered in Nashik, Jindal Poly Films Ltd. is a major producer of polyester and polypropylene films used in flexible and specialty packaging. Its product portfolio includes BOPP, PET, and CPP films widely used across food, consumer goods, and industrial applications. Film prices generally range from ₹120–₹260 per kg. The company benefits from a backward-integrated supply chain and ongoing capacity expansion driven by recent investments.

5. Huhtamaki PPL Ltd.

This packaging company has wide horizons in the global market, specializing in overall packaging solutions. The company’s objective is to fulfill the primary packaging and labeling for various industries like Food and beverage, Pharmaceutical, and personal care brands. They have a diverse range of products for various premium to mid segments, typically priced between ₹7–₹20 per piece.

6. Polyplex Corporation Ltd.

Polyplex Corporation is a Noida-based firm and a leading manufacturer of packaging solutions, offering BoPET polyester films. The company mostly focuses on electrical insulation packaging solutions and industrial equipment packaging. The price of their products falls between ₹150–₹300 per kg.

7. Manjushree Technopack Ltd.

Manjushree Technopack Ltd. is a Bangalore-based firm and a prominent player in the manufacturing of packaging materials. They have been supplying a wide range of packaging materials, such as PET, HDPE, PP bottles and containers to FMCG groups, dairy industries, and pharmaceutical industries. The container price range falls between ₹10–₹50 per unit. They are well known for customization options according to the project requirements.

8. Cosmo Films Ltd.

Cosmo Film Ltd is a Delhi-based packaging material manufacturing company for specialty films and BOPP. They are widely known for lamination and flexible packaging solutions across various markets. Their products usually fall between ₹140–₹280 per kg.

9. Balmer Lawrie & Co. Ltd.

Balmer Lawrie & Co. Ltd. is a leading, reputable, and long-established packaging solution manufacturer offering multi-material packaging and covering a large segment of industries continuously for many years. They offer a wide range of packaging materials like barrels, large containers, and heavy-duty sustainable packaging for various industries and sectors. Their industrial packaging products typically start from ₹1,000 per unit and above.

10. Parksons Packaging

Parksons Packaging is an India-based company known for carton and specialty packaging solutions. It serves retail, FMCG, and luxury product segments with a strong focus on visual appeal and innovation. Customized cartons and packaging solutions generally range from ₹10–₹50 or more per unit. Parksons stands out for its design-centric approach and increasing use of sustainable packaging materials.

Types of Packaging & Applications

It is necessary to understand types sof packaging solutions provided by above above-listed brands and companies.

| Packaging Type | Common Uses |

| Flexible films & pouches | Snacks, beverages, and pharmaceuticals |

| Laminated tubes | Toothpaste, cosmetics, creams |

| Folding cartons | Liquor, pharma, retail boxes |

| Rigid plastic containers | Bottles for liquids, chemicals |

| Polyester/BOPP films | Labeling, lamination, barrier packaging |

Features to Look for When Choosing a Packaging Company

1. Material & Quality

- Barrier properties (oxygen/moisture resistance)

- Food-grade certifications (FDA, ISO)

2. Sustainability

- Recyclable or biodegradable materials

- EPR (Extended Producer Responsibility) compliance

3. Customization & Design

- Print quality & graphics

- Shapes, sizes, and structural design

4. Cost & Scale

- Competitive pricing

- Minimum order quantity (MOQs)

5. Delivery & Support

- Lead times and logistics reliability

- Technical support and R&D partnership

Typical Price Considerations (2026)

Pricing varies widely based on material, print quality, volume, and customization:

| Packaging Type | Approx. Price |

| Flexible pouches | ₹6–₹12 per pouch |

| Printed films | ₹150–₹300 per kg |

| Laminated tubes | ₹5–₹30 per tube |

| Cartons | ₹8–₹50 per piece |

| Plastic bottles | ₹10–₹50+ |

Final Thoughts

India’s packaging landscape in 2026 balances innovation, cost-efficiency, and sustainability. Whether you’re sourcing flexible packaging for food products, premium cartons for retail goods, or industrial containers for liquids or chemicals, there’s a top-tier company to match your needs. However, if you are looking to procure packaging materials and solutions in bulk, Moglix is the right platform to purchase them efficiently. Moglix ensures the procurement of primary, secondary, tertiary, and sustainable packaging at the most competitive prices from reputed and reliable brands, delivering to thousands of pin codes across India.