Packaging and E-Commerce: Meeting the Demands of Online Shopping in a Greener Way

Packaging and E-Commerce: Meeting the Demands of Online Shopping in a Greener Way

Packaging and E-Commerce: A Green Revolution for Online Shopping

Packaging plays a pivotal role in a world where online shopping is the new norm. Did you know that over 2.14 billion people will buy online by 2021? (Source: Statista) But there’s a pressing issue we can’t ignore – the environmental impact of packaging. Let’s unravel the dynamic relationship between packaging and e-commerce while unveiling innovative strategies to meet the demands of online shopping sustainably.

The E-Commerce Wave: A Greener Path Ahead

As the digital shopping realm expands, packaging finds itself at a crossroads. Striking a balance between convenience and eco-friendliness is the challenge we tackle today.

The Packaging Puzzle: Unveiling the Dilemma

Why should you delve into this? The answer is clear: our planet’s health is at stake. The heaps of packaging waste – from plastic to cardboard – contribute to a looming environmental crisis. As consumers, we hold the power to advocate for change and steer e-commerce in a greener direction.

Innovative Packaging: Shaping Tomorrow, Today

- Smart “Right-Size” Approach: Opting for packaging that fits products snugly minimizes waste and enhances shipping efficiency.

- Eco-Materials Revolution: From recycled materials to biodegradable alternatives, businesses are embracing packaging materials that nurture, not harm, the environment.

- Less is More Philosophy: Embracing minimalist packaging not only reduces waste but also simplifies recycling processes.

The Time for Change: The Call to Action

Change isn’t a distant concept; it’s urgent. With landfills overflowing and our oceans drowning in plastic, the time for change is now. Our urgency isn’t just for today’s convenience; it’s for preserving a thriving world for generations to come.

The Data-Driven Path: Unmasking the Value

Data speaks volumes about the value of sustainable packaging. Research shows that consumers are willing to pay extra for products housed in eco-friendly packaging. (Source: Forbes) This isn’t a fleeting trend; it’s a transformative shift in consumer behavior.

Your Role: A Green Shopping Agenda

Pick Smartly: Opt for products with minimal packaging to reduce waste.

Champion Green Brands: Support businesses that prioritize eco-conscious packaging.

Spread Awareness: Educate others about the impact of packaging on our planet and encourage eco-friendly choices.

Conclusion: Packaging, E-Commerce, and a Greener Future

As e-commerce reshapes our shopping habits, let’s reshape our planet’s destiny too. Sustainable packaging isn’t just a notion; it’s a revolution in responsible consumption. With every online purchase, we cast a vote for a more sustainable future. Let’s make our choices count, ensuring that convenience and environmental consciousness go hand in hand.

Beyond Greenwashing: Authentic Strategies for Implementing Sustainable Packaging

Beyond Greenwashing: Authentic Strategies for Implementing Sustainable Packaging

Did you know that packaging accounts for 40% of the global plastic consumption? This is ironic, considering that over 70% of consumers are willing to pay for green packaging. In fact, more than one-third of people would buy additional green-packaged products if they could find them easily with clear labels.

With consumer focus shifting rapidly, your brand image could be impacted if your business still hasn’t adopted eco-packaging solutions. Continue reading to find out which trends to adopt.

Trends and Innovations in Eco-Friendly Packaging

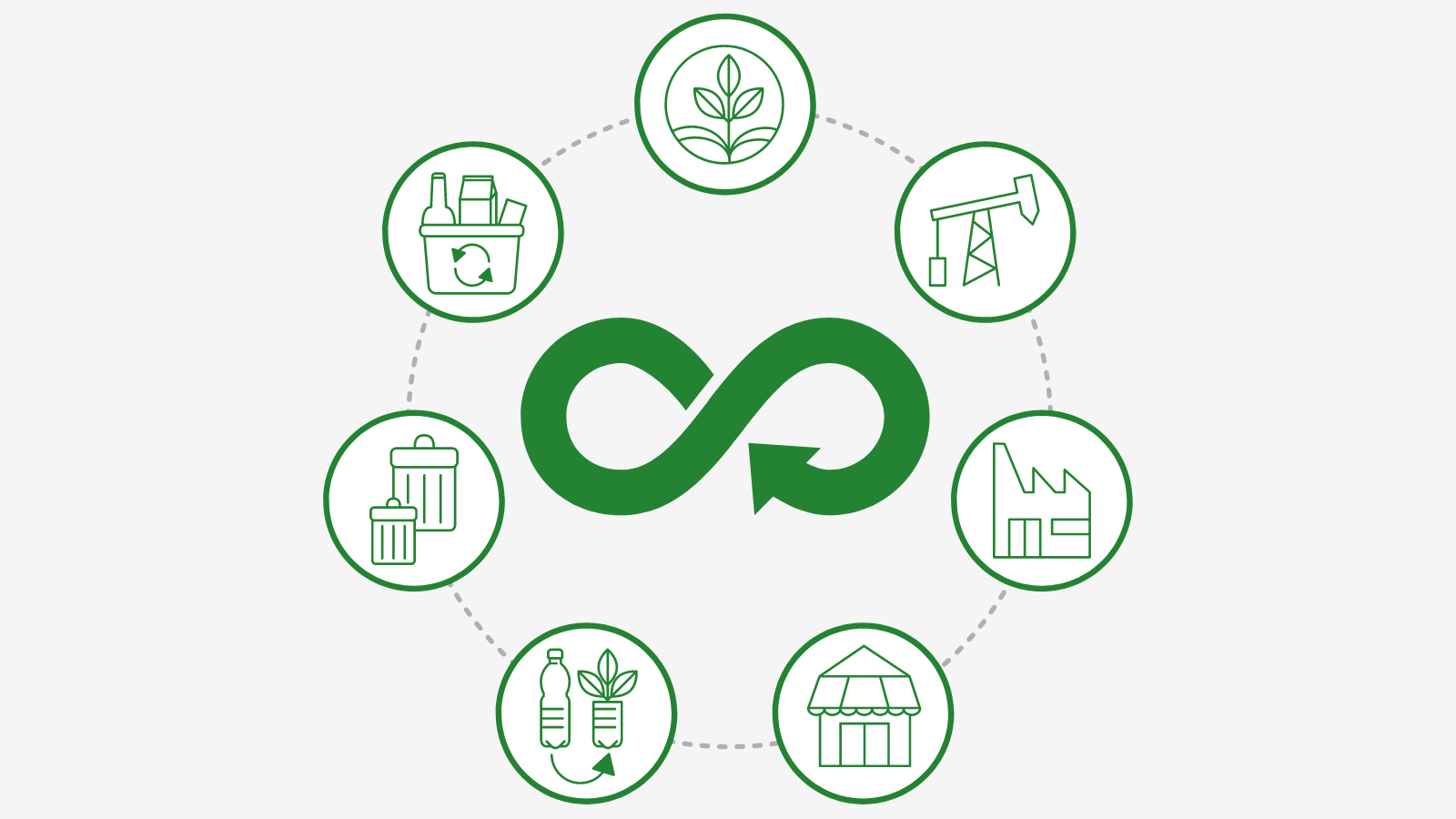

Eco-friendly packaging is a key component of a circular economy, which is a model of production and consumption geared towards waste reduction, recyclable materials, and regenerating nature.

To achieve this, your eco-packaging solutions must consider the environmental aspects of the entire life cycle of a product or service — from raw material extraction to disposal or recycling. This process is known as life-cycle assessment.

However, not all green packaging claims are trustworthy. Greenwashing can occur when you promote one sustainable stage of the life cycle but ignore another harmful stage. For example, a company may use recycled plastic for packaging but ship products using harmful modes of transportation.

So if you are a manufacturer or retailer, consider the following trends in packaging sustainability designed with the principles of circular economy and life cycle assessment.

Packaging Trends

You can achieve packaging sustainability by following these eco-packaging trends:

- Upcycling: It transforms used products into new sustainable materials or products with more value than the original ones. For example, upcycling a tire into a coffee table.

- Sustainable sourcing: It involves selecting environmentally-conscious suppliers and renewable or remanufactured materials. Begin implementing sustainable sourcing by communicating your sustainability goals to suppliers.

- Green Logistics: Integrating environmental considerations into logistics minimizes their ecological impact and maximizes efficiency. Companies can implement green logistics using green transportation, sustainable materials, and energy-efficient factory practices.

Packaging Material

To keep up with changing consumer demands and environmental challenges, here are some packaging innovations you can adopt:

- Convert fibers from fishing nets and ropes into high-grade plastic to package products or to make bottles.

- Water soluble packaging for high-quality eco-friendly garment bags.

- Seaweed is another sustainable packaging innovation for making food takeaway containers.

Packaging Design

Here are some sustainable design trends for packaging coveted by consumers:

- Use plant-based dyes to create a safe and environmentally-friendly look for your package design.

- Using reusable or refillable packaging — like fabric bags — promotes waste reduction and decreases carbon footprint.

- Minimalist package design is a sustainable design option that reduces space during transportation, reducing your carbon footprint.

Click here to learn more about how Moglix can help you implement sustainable packaging in the supply chain.

Optimizing Packaging Operations: Strategies for Achieving Operational Efficiency

Optimizing Packaging Operations: Strategies for Achieving Operational Efficiency

Did you know the global packaging industry is estimated to grow over $80 billion by 2023? Packaging operations are essential to any industry and manufacturing or distribution process. Optimized packaging operations involve improving the efficiency and effectiveness of the operations by eliminating waste, reducing costs, increasing output, and improving quality.

But process optimization for packing operations is not just about ensuring proper packaging equipment and machinery. It is also about designing and implementing efficient packaging strategies and continuously optimizing them to reduce costs and increase efficiency and output. How? Continue reading to find out.

Strategies to Achieve Packaging Efficiency

1. Automation and technology

In Q1–2022, companies in the US, Canada, and Mexico increased usage of industrial robots by nearly 30% and the robotics industry experienced a 40% surge in revenue. One of the major reasons is that automation and technology usage can increase efficiency by speeding up the packaging processes. It can help you save time and money by reducing the need for human intervention — while improving packaging quality and consistency.

2. Supply Chain Integration

Supply chain integration can help you streamline processes and improve customer service by smoothing out communication. It can improve collaboration within parts of the supply chain, making it easier to troubleshoot issues. A seamless integration with the supply chain enhances the visibility of varying packaging stages and improves cooperation and risk management.

3. Standardization and Modular Design

Standardization means using standardized components for different products or purposes. Modular design, conversely, means dividing a complex product into smaller units that can be easily assembled and disassembled.

Standardization and modular design can help you make products easily, make repairs easy, reduce waste, and optimize resource consumption. It can also improve productivity and profitability.

4. Inventory Management

Inventory management can help businesses minimize the cost of inventory by helping them reduce warehouse space, avoiding label stock-outs, and improving supplier relations. An inventory management software can use your historical data to forecast demand and align your production and delivery processes around anticipated packaging needs. Over time, all of these factors can impact your bottomline.

5. Quality Control and Testing

Quality control and testing in packQuality Control and Testingaging operations are processes used to ensure that packaging methods and materials are suitable, safe, and comply with industry standards. Proper control and testing can help you optimize a package by helping you prevent or minimize the risk of product damage, contamination, leakage, or loss during transport.

It can also ensure that your product has adequate protection, presentation, and information for the consumer. This way, it can improve the efficiency of your packaging operations by reducing waste, rework, recalls, and complaints.

Moglix makes process optimization for packaging operations easy by going over and beyond the packaging equipment and machinery; click here to find out how.

Reducing Carbon Footprints: The Cement Industry’s Path to Sustainability

Reducing Carbon Footprints: The Cement Industry’s Path to Sustainability

The global cement industry produces an estimated 4 billion tons of material yearly fueling infrastructure that shape our daily lives, while contributing whopping 7% of global emissions. With this, the industry stands at a critical juncture. The good news is that the cement industry is waking up to its responsibility and is taking bold steps towards a greener future, innovating eco-friendly cement and sustainable packaging solutions.

In the wake of this, the World Cement Association has announced its goal to reduce CO2 emissions by the cement industry by at least 25% by 2030.

Future forecast: 3 trends in interactive packaging that could be the new normal in 2023

Future forecast: 3 trends in interactive packaging that could be the new normal in 2023

Three trends that could define interactive packaging in 2023 and beyond

When it comes to packaging today, attractive and informative no longer suffice. Instead, interactive packaging could be the new benchmark for leaders in the packaging industry to pursue. Designed to create consumer engagement in one way or the other, interactive packaging creates a deeper connection between the customer and your brand. It can be through technology, such as QR codes or augmented reality features, or through more conventional channels, like packaging that includes games or puzzles.Here are some popular types of interactive design that could revolutionize packaging across the F&B, electronics and even the cosmetics industry in 2023 and the years that follow.

Technology-based interactive packaging:

Technology can be used in packaging to create an interactive experience for the consumer. Popular examples of this kind of design include touchscreens, QR codes, and even augmented reality on the package. Plant-based snack company Mezcla excelled at this type of packaging when it included a QR code on the package. Customers could scan the code to view artwork submitted by others worldwide and even submit their own.

Game-based interactive packaging:

Gamification is also succeeding at delighting customers and transforming packaging today. This type of packaging includes games or puzzles that the consumer can solve or play as part of the packaging experience. India’s most popular jam, Kissan, chose this route when it included a kid-friendly board game as a part of its jam packaging.

Customizable packaging:

This packaging allows the consumer to personalize the packaging by adding their own artwork or photos. Kokoa Hut put a brilliant spin on this idea by offering bags that buyers could customize. The bags contained tiny square boxes that could be flipped upward to create distinct images or text. Customers could play around with this feature and create custom texts like their name or a symbol like a heart or a star on their bags.

Future focus: Is interactive packaging the future?

Packaging now matters almost as much as the product, and in the coming years, the rise of interactive packaging as a preferred alternative to traditional options is perhaps inevitable. As a bonus, interactive packaging can be used for various products, including food, cosmetics, and consumer electronics.

Further, interactive and intelligent packing opens up a new avenue for successful customer engagement, which can be a fun and novel experience for the end user. Positive interactions like this can improve your top line because research reveals that around 72% of customers share good brand engagement and experiences with at least six others.

Want to stay ahead of the curve? A competent packaging solutions provider can help.

With the packaging industry’s landscape changing dynamically and supporting new trends in recent years, it is crucial to have a competitive edge today. Give your business the advantage it deserves by partnering with a comprehensive packaging solutions provider like Moglix. We offer extensive services in this domain, including vendor and inventory management, quality control and compliance and primary, secondary as well as tertiary packaging solutions. Visit our website to learn more.

A closer look at corrugated box packaging: And why it is the future of a circular economy

A closer look at corrugated box packaging: And why it is the future of a circular economy

Why corrugated boxes fit perfectly into the narrative of a circular economy

The American Forest & Paper Association had some encouraging news to report last year; a colossal 91.4% of old corrugated containers (OCCs) were recycled in the U.S. in 2021. Also, corrugated packaging ranks among the most recyclable options elsewhere in the world. This makes it a natural choice to pursue a circular economy, where resources are used, reused, and recycled in a closed loop — thus preserving natural resources and minimizing waste and pollution.

But even beyond their recyclability alone, corrugated boxes are the ultimate expression of a circular economy because they are sustainable across the product life cycle, from manufacture to recycling. Here’s how.

Manufacture and production

Life cycle assessment reports reveal that corrugated box manufacturers in the U.S. have been increasingly switching to renewable energy sources and simultaneously reducing greenhouse gas emissions. Elsewhere in the world, too, corrugated box production is highly sustainable, and with good manufacturing practices we can get good strength with higher percentage of recycled content.

Even in the regions that rely on fossil fuels for box manufacture, it can be relatively easy to make the transition to green energy sources that are also highly sustainable. This makes corrugated packaging a distinct example of circularity at the production stage.

Supply chain sustainability

Throughout its product life cycle, corrugated packaging is an integral part of the supply chain in various industries across the globe. From food and beverages, e-commerce, and office supplies to more sensitive products like electronics and healthcare equipment, corrugated boxes are perfectly suited to house many goods.

Sustainability is one of the key reasons driving the popularity of this packaging material. This, coupled with other valuable characteristics like rigidity, customizability, and scalability, only strengthens the case for circularity in corrugated packaging.

Reuse and recycling

Among the most recycled materials on the planet, corrugated boxes remain sustainable even toward the end of their usable life cycle. However, this is an area that requires a fair bit of streamlining, mainly when the boxes are used in last-mile delivery.

Since many end users are unaware of the high recyclability quotient of corrugated boxes, the cartons are often misdirected to landfills and other wastelands, pulling down the overall percentage of packages that can be put back into circulation. Awareness programs and conscientiousness among end users can reverse this situation and further improve the impressive role of corrugated boxes in a circular economy.

Want to give your business an advantage in the race to circularity?

Making the switch to corrugated box packaging or other recyclable packaging wherever possible could be a great place to begin. Moglix can be your ally in this challenging yet crucial transformation to sustainable solutions. Our end-to-end packaging procurement solutions can make the journey to circularity easier and quicker for you. Visit our website to learn more.

Moglix empowered India’s fastest growing investment firm redefine packaging for its fashion, home and beauty and personal care brands through in-bound packaging supply chain.

Moglix empowered India’s fastest growing investment firm redefine packaging for its fashion, home and beauty and personal care brands through in-bound packaging supply chain.

Moglix empowered India’s fastest growing investment firm redefine packaging for its fashion, home and beauty and personal care brands through in-bound packaging supply chain.Read More

The Top 8 Industries that Use Corrugated Box Packaging

The Top 8 Industries that Use Corrugated Box Packaging

Corrugated materials are among the most popular kings of box packaging used worldwide. Leading market researcher IMARC group pegged the size of the corrugated box market at $198 billion last year and expects the market to nearly hit the $230 billion mark by 2028.

A significant portion of this tremendous growth can be traced back to certain select industries that rely significantly on corrugated box packaging. Here are eight such market segments.

Food and beverages

Corrugated boxes are particularly suitable for packaging and storing food products because they offer a unique advantage — resistance to bacterial infections. Since they keep the food items fresh, germ-free, and safe, these cartons are widely used in the F&B sector.

E-commerce

Corrugated packaging is easily the backbone of the e-commerce industry owing to its various benefits, like easy customization. Cartons come in different sizes to suit a wide range of products in the e-commerce supply chain and can be personalized to reflect brand values.

Office supply and stationery

The office supplies market worldwide is expected to increase at a CAGR of 1.9%, from USD 130.5 billion in 2021 to USD 149.4 billion by 2028. Corrugated packaging is integral to this booming industry for reasons ranging from scalability to availability and longevity.

Textiles

Packaging for textiles and apparel needs to be attractive, fuss-free, and indicative of the brand’s unique signature. Corrugated packaging helps check all these boxes, making it one of the preferred solutions in the textile industry’s supply chain across the world.

Luxury goods

Corrugated packaging is the only rigid medium that can be cut and folded into infinite shapes and sizes. This unique blend of customizability coupled with strength has made it a trendy packaging solution in the luxury goods market.

Healthcare

Whether it involves transporting medicines and pills or sensitive and delicate medical equipment, corrugated box packaging can be ideal for many reasons. It is rigid, hygienic, and easy to manufacture in different shapes to pack equipment of different sizes snugly.

Electronics

Although it’s easy to overlook, electronic products can be extremely fragile. Therefore, nothing but the sturdiest and safest packaging will do when they are shipped over long distances and across borders. The electronics industry, it appears, has found its solution in corrugated packaging.

Hazardous materials

Corrugated packaging can also be made water-resistant and highly tolerant to temperature changes. These attributes are why it is a preferred packaging material for transporting hazardous materials, batteries, etc.

Need corrugated box packaging? The right packaging solutions can make procurement a breeze.

Most corrugated box packaging is 100% recyclable, making them an excellent choice if your business is keen on increasing its sustainability quotient. Moglix can make it easy to procure the best-corrugated packaging for your primary, secondary and tertiary packaging needs. Visit our website to learn more.

Trend watch: Top 7 types of packaging materials that are industry favorites today

Trend watch: Top 7 types of packaging materials that are industry favorites today

The global packaging market is one of the fastest-growing economic segments today. In India, too, the packaging industry — worth over $917 billion in 2019 — is growing at a CAGR of 2.8% and is expected to hit the $1.05 trillion mark by 2024. If your business operates in this dynamic market segment, it is imperative that you remain aware of what’s driving the packaging sector and what your peers are doing.

One such essential trend to watch is what packaging materials are the industry favorites in the current scenario. Here’s a closer look at the seven most common packaging materials businesses use today.

1. Paperboard boxes

Boxes made of paper and paperboard are among the most common types of packaging used today. Paperboard is available in different varieties like kraft paper and SBS paperboard. It is typically preferred by businesses in the food and beverage industry, although paper packing is also standard in transporting electronics, cosmetics, chemicals and even heavy goods.

2.Corrugated boxes

Valued at $70 billion in 2022, the corrugated packaging market is one of the fastest-growing segments in the industry. Since most corrugated boxes are entirely recyclable, this is one of our most sustainable packaging options. Corrugated packaging is suitable for various products like food, textiles, electronics, healthcare goods and more.

3.Plastic packaging

Plastic packaging is everywhere, from bottles and boxes to cups and bags. Data shows us that the global plastic packaging market is growing at a CAGR of 4.2% today. Despite this, plastic remains a global concern since it is highly unsustainable. It is why many companies prioritise using plastic-free packaging, or at the very least, recyclable plastic.

4.Rigid box packaging

A tad bit more luxurious than corrugated boxes and paperboard packaging, rigid boxes are around four times thicker. So, they are typically preferred for premium products like mobile phones, jewelry, watches, expensive electronics and other luxury goods. In addition to being sustainable, rigid boxes also offer superior product protection and brand value addition.

5.Metal packaging

The growth of e-commerce and retail, the rise in global Predominantly used in the food and beverage industry, metal packaging can be sustainable depending on the material used. Aluminum tops the list of sustainable metal packaging since it is easy to recycle and results in minimal wastage. Tin is also another sustainable packaging option in this category.

6.Glass packaging

Glass is also a sustainable choice for businesses looking to switch to plastic-free packaging. Best suited for premium food and beverage products, glass packaging is also preferred for other products like chemicals, medicines, cosmetics and more. But, on the flip side, it is pretty expensive and fragile.

7.Flexible packaging

Due to its ease and convenience, flexible packaging is quickly becoming one of the industry’s most preferred types of packaging. This kind of packaging is cost-effective, and rescues waste. It is made from pliable materials like paper, foil, coated paperboard or polymer films.

What packaging materials are you choosing today?

There’s no denying that it’s easy to opt for the most common packaging materials in the market. However, sustainable options like plastic-free and recyclable packaging are the need of the hour. And businesses keen on remaining at the top of the game over the long run need to strike the right balance between what’s easy and what’s right.

A competent packaging solutions provider like Moglix can help you make the right choice with innovative and competitive primary, secondary and tertiary packaging solutions. Visit our website to know more.

Moglix Enables India’s Largest food delivery services to transform packaging solutions ranging from primary to tertiary packaging material.

Moglix Enables India’s Largest food delivery services to transform packaging solutions ranging from primary to tertiary packaging material.

Moglix Enables India’s Largest food delivery services to transform packaging solutions ranging from primary to tertiary packaging material.Read More