Contract Manufacturing Advantages: A Comprehensive Guide

Contract Manufacturing Advantages: A Comprehensive Guide

Contract manufacturing is growing a lot, especially in the Asia-Pacific area. Industries like electronics and pharmaceuticals are driving this growth. The global market is expected to grow by 5.3% each year from 2021 to 2030.

Along with the rising demand for custom goods and services, this trend shows how contract manufacturing can help save money and spark new ideas.

Companies can reach their goals, meet their needs, and keep the high standards they want when they work with makers to outsource production. The contract manufacturer produces the goods, tests them, and sends them to the purchasers.

Contract manufacturing vs. Traditional manufacturing (OEM)

Businesses often contemplate between contract manufacturing and OEM. They look at cost, control, and speed. A survey asked this to 163 industry professionals, and 85% chose contract manufacturing. Businesses aim to use resources better and want to focus on core tasks.

Contract manufacturing improves quality and brings new ideas. OEM offers more control and protects intellectual property. However, OEMs cost more and need to be more flexible. This shows contract manufacturing meets market needs and supports industry growth.

Outsourcing Manufacturing: Benefits

Last year, Apple started to make 12 billion iPhones in India. They focused on buying parts locally and making assembly better. Outsourcing manufacturing is getting more common. This way, they save money and get other big benefits, too.

- Proximity to End Customers: McKinsey has found less international shipping of products now. More goods are being made and sold locally, especially in growing markets. A good example is how semiconductor chips are made in Asia for local customers. This helps cut down on shipping costs and makes delivery faster.

- Operational Savings: By outsourcing, firms can close or make their local plants smaller. This lets them focus more on research and development and helping customers. It also cuts operation and ownership costs.

- Access to Raw Materials: Costs can go down for local manufacturers close to the source of raw materials. This is helpful for fields that need a lot of different materials, like the semiconductor industry.

- Specialized Suppliers: Dedicated suppliers are available in manufacturing hubs such as Asia. Local manufacturing makes precision equipment and technology more affordable.

- Product Development Expertise: Some countries are popular for contract manufacturing. For instance, Malaysia is an expert in electronics. It helps big companies like GE and Siemens produce faster and cheaper goods.

- Specialized Personnel and Equipment: Outsourcing allows access to special machines. It helps hire skilled people for short jobs. This means we don’t need temporary workers. We also don’t need to buy expensive equipment.

- Ease of Product Movement: Contract Manufacturers who know trade laws can move products easily between countries. This lowers the risk of legal problems.

Advantages of partnering with a contract manufacturer

In 2023, Intel partnered with eight companies in India to make laptops locally. They did this for a few smart reasons:

- Saving Money: Making things in India costs less because the workers and materials are cheaper. Intel doesn’t have to spend much money setting up its factories.

- Making Better Laptops: By working with these Indian companies, which are good at what they do, Intel can ensure their laptops are of high quality and get to customers without delay.

- Reaching More People: Intel is also changing some of their laptops so they can sell them in India and other new places where people are looking for good, affordable technology.

- Making things this way helps Intel save money, make better products, and sell to more people worldwide. It’s a clever plan to grow their business and develop new ideas.

Best practices for risks and compliance management

Your Request for Proposal (RFP) is very important when choosing a contract manufacturer. It helps you pick the best one by looking at their services, financial health, tech skills, and legal compliance. Make sure they have a strong history of success, know what they are best at, and can handle your project’s tech needs. Be careful about risks, like protecting your ideas and checking all legal details.

Final words

Companies can now choose where to make their products worldwide. This use of special skills and cost cuts has made manufacturing global. China is a big player in electronics and consumer goods. Southeast Asia, Eastern Europe, and Latin America are also important. The choice depends on labour costs, infrastructure, and how stable a place is.

To navigate the global manufacturing shift, learn more about partnering with contract manufacturers through insights from Moglix.

Navigating Seasonal Packaging Trends for 2024

Navigating Seasonal Packaging Trends for 2024

52% of consumers make repeat purchases from brands with unique packaging. Brands are finding new ways to make their product packaging match what customers want. They use cool designs made of recycled materials that match the seasons, like Christmas or summer. Let’s understand what new seasonal packaging trends you might see in stores this year.

Understanding what consumers like in Packaging

Did you know that 72% of people are more likely to buy items in a cool package? There are many things to consider to make a package look great. For instance, lots of folks love packages with bright colors and fun pictures, which makes them want to choose that item more than others. Besides making it look fun, companies also consider who will buy their stuff, like how old they are or if they live in the city or the countryside, and consumer behavior to make their packages look super appealing.

Top 2024 Packaging Innovations and Seasonal Market Trends

Sustainable Packaging

Nearly 69% of consumers are ready to bear extra costs for sustainable products. That is why sustainable packaging is the trend. In this regard, brands use eco-friendly materials to align with customer values. This also helps companies meet sustainability demands while maintaining packaging quality per consumer preferences.

Minimalism in Design

The demand for minimalist package design is also accelerating. As per the latest survey, around 76% of consumers like product packages with clean lines, simple color palettes, and uncluttered designs. All it takes is to bring sophistication and authenticity to stand out on those crowded shelves in that minimalist packaging aesthetics.

Interactive packaging

Big e-commerce platforms like Flipkart, Myntra, and Amazon also use interactive technologies (e.g., QR codes) in the packaging to increase consumer engagement. For instance, the QR code allows access to additional product information through the mobile device that brands find hard to fit into the package design.

Custom packaging

Big brands like Birchbox, L’Oreal Color & Co hair dye, Concrete Jungle, and Le Petit Trou have nailed custom packaging. Custom packaging means making packages that match special times of the year or big events. When companies put pictures or words that customers choose on the package, the product feels special and exciting. This also helps people recognize and love the brand more while meeting consumer preferences.

Limited edition (seasonal) product packaging

Limited edition packaging is when companies make special packages for certain times of the year, like Christmas or Halloween. They use colors, symbols, and pictures that remind people of that holiday or season. This makes customers feel happy and remember good times, which makes them more interested in buying the product and helps the company sell more.

End Thoughts

The packaging industry is seeing new packaging market trends based on consumer behavior. Brands are now paying more attention to personalized packaging to increase customer satisfaction. Focusing on completely sustainable packaging solutions is the best approach to staying ahead in the market.

Looking for ideal future-proof packaging solutions? Partner with the right packaging solution provider.

Choose Moglix to leverage the latest packaging innovations for long-term relevancy and impact. Visit our website to learn more.

The Life Cycle of Corrugated Packaging, why Recycling Matters

The Life Cycle of Corrugated Packaging, why Recycling Matters

Corrugated packaging boasts a recycling rate of about 30% in India, one of the highest among packaging materials. This high recyclability indicates the degree of responsibility we have in managing its life cycle effectively. Understanding this cycle is the key to realizing why recycling isn’t just beneficial but essential for our planet. In this regard, this article covers the life cycle of corrugated packaging and highlights the vital role of corrugated recycling in fostering a sustainable future.

The Life Cycle of Corrugated Packaging

Corrugated packaging has a fascinating life cycle. It goes as follows.

- Creating the board: Corrugator, a key machine in this process, brings together three to seven sheets of paper to form a single, double, or triple wall board. This is a continuous process where sheets are corrugated, glued and cut to size.

- Corrugation: The process involves giving a v-shape to the medium sheet of paper (fluting) under heat and pressure, then applying starch and gluing it with inner and outer liners to form a rigid board.

- Converting: Post corrugation, the board undergoes various transformations like printing, die-cutting, folding, and gluing, as per custom requirements.

Recycling Significance and Process from Bin to New Packaging

Recycling cardboard is important for environment conservation and resource management. In this regard, recycling corrugated material reduces the volume of waste and landfill. This reduces the amount of methane emission to the environment which is 28 times more toxic than carbon dioxide. The cardboard reuse process is a fascinating cycle as described below.

- Collection and Transportation: Collection of recycled materials from different sources and transporting them to recycling centers.

- Sorting and Cleaning: Sorting collections using infra-red or air jets followed by cleaning them to remove contaminants.

- Shredding and Pulping: Shredding and mixing the collections with water to create a pulp to remove impurities before breaking them down into smaller pieces.

- Processing into raw material: Processing the output into raw forms, for instance, processing paper pulp into new paper rolls.

- Manufacturing new products: Sending raw materials to various manufacturers to be made into new materials.

- Distribution and usage: Distributing manufactured products into stores and businesses to be used by consumers.

- Consumer participation: Consumers choosing to recycle the product thereby completing the recycling life cycle.

Reduction achieved

The environmental impact of packaging is noteworthy. Between 2006 and 2020, the corrugated industry reduced greenhouse gas emissions per unit by 50%. This is a tremendous achievement towards tackling climate change. There was also a significant reduction in:

- Ozone depletion (13%)

- Energy usage (13%)

- Water usage (18%)

- Acid rain (41%)

- Smog (44%)

- Respiratory effect (54%)

- Eutrophication (30%)

Recycling rate

In 2022, the recycling rate of cardboard, including corrugated packaging, reached a remarkable 93.6% in the US, an increase from 91.4% in 2021. This makes corrugated packaging one of the most recycled materials in the country.

Benefits of Corrugated Packaging Recycling

Corrugated packaging recycling offers several environmental benefits. Here are some key benefits:

- Being sturdy, corrugated materials offer a higher weight capacity than traditional packaging.

- Corrugated packaging offers high customization to reduce waste production.

- They offer highly recycled material, aiding towards sustainable disposal and low carbon emission.

- A single corrugated box can be recycled and reused multiple times, making it affordable for companies.

- The use of new and recycled fibers supports a circular economy in packaging, maximizing resource efficiency.

Challenges and Innovative Solutions in Recycling Corrugated Packaging

The corrugated packaging industry is facing two biggest challenges.

- Supply-demand gap: There is a potential shortage of recycled paper products. With a growing demand for eco-friendly materials, there’s a risk of not meeting these sustainability goals.

- Collection levels: Despite high recycling rates, collection levels of high-quality recycled materials are expected to remain almost flat.

In this regard, the following innovative solutions can help.

- Enhance PET recovery from collection to sorting and processing

- Public-private partnership to boost local collection rates

- Improving sustainable packaging design to enhance material recovery

Global Perspectives on Corrugated Packaging Recycling

Globally, corrugated packaging recycling holds significant importance in sustainable waste management and resource conservation. For instance, in Europe, the recycling rate of corrugated cardboard is 82%, aiding the region’s circular economy and cardboard sustainability. Similarly, in the US, more than 93% of old corrugated containers were recycled in 2022, a significant jump from 54% recycling rates in 1993.

End Thoughts

Adopting corrugated box packaging could be your crucial transformation to sustainable solutions. In this regard, Moglix offers end-to-end corrugated packaging procurement solutions. Our personalized sustainable packaging options aim to meet your enterprise needs while driving you towards the forefront of green packaging solutions.

Revolutionizing Packaging: Adapting to a Post-Pandemic World

Revolutionizing Packaging: Adapting to a Post-Pandemic World

The COVID-19 pandemic has significantly impacted and transformed several industries, including the $413 billion per year Indian packaging industry. The industry started to face post-pandemic unique challenges with heightened concerns over hygiene and safety, but also rapidly shifted towards innovations in ways previously unimagined.

Pre-Pandemic Packaging Trends

Before the pandemic, the packaging trends slowly evolved towards sustainability and minimalism. However, the pandemic brought a growing demand for recycled packaging amidst the rising concern for curbing 3.4 MT of plastic waste yearly. Packaging trends post-pandemic are majorly driven towards:

- Hygiene and Safety: The need for safe, virus-free packaging led to a surge in ban of single-use plastics

- Materials for sustainable packaging innovations: Aimed towards developing hygienic yet eco-friendly packaging solutions

Sustainability Amidst Safety Concerns

Despite the heavy demand for single-use plastics, there is still a trend for sustainability. The packaging industry is exploring various eco-friendly materials to reduce environmental impact. This is because of customer demand. As per the research, 69% of consumers are willing to pay more for sustainable products. These statistics underscore a strong market demand for eco-friendly packaging.

Eco-Friendly Packaging Materials and Practices

With a notable CAGR of 15.06%, India’s biodegradable packaging market is on the rise. In this regard, there is a notable trend in sustainable packaging, achieving lightweight. The aim is to reduce material weight to conserve resources and cut down on energy consumption with ease. The list of eco-friendly materials in demand are:

- Paper with recycled content

- Jute

- Sugarcane fiber (Bagasse)

- Corn and starch

- Wood – FSC certified

E-commerce packaging Boom

There has been a significant increase in the need for eco-friendly e-commerce packaging strategies post-pandemic. According to recent data, 2.3 billion consumers did online shopping at least once in 2022. While consumers are intending to spend double on online grocery stores, e-commerce industries are using smart packaging tactics using customer psychology. For instance, companies are using color psychology: blue for cleanliness, red for pleasure, and green for health-related packaging.

Consumer behavior and packaging preference

Consumer preferences in packaging have shifted significantly towards sustainability and minimalist packaging. 60% of Indians are willing to pay a premium price for sustainable products. Consumers increasingly want to understand the environmental impact of packaging materials. In this regard, packaging industries are exploring every type of recycled material, from recycled materials to biodegradable alternatives.

Also, there is a growing trend towards minimalistic packaging. It aligns with customers’ sustainability goals while simplifying recycling processes for industries.

Regulatory Changes in Packaging and Industry Responses

Governments worldwide have been revising regulations on the use of single-use plastics. For instance, India imposed a ban on 19 single-use plastic items on 1 July 2022 to push the industry towards sustainable solutions. On the other hand, the industry response to packaging challenges is also incentivized to adopt sustainable packaging practices.

Future Trends in Packaging

The packaging industry is witnessing several trends that are going to shape the future of packaging, such as:

- Smart packaging: With 20% environment-conscious Indian consumers, the packaging industry aims at enhanced consumer engagement and product tracking using smart packaging technologies.

- Circular economy models: A shift towards reuse and recycling of packaging materials to reach the circular economy of Rs 14 lakh crores by 2030.

- Customization and consumer experience: Shifting focus towards creating an engaging unboxing experience as 60%-80% consumers want a “Wow” factor.

End Thoughts

The pandemic has transformed the packaging industry as a beacon of innovation and growth. The industry is more focused towards creating customized packaging solutions to promise protection and deliver higher customer satisfaction. In this regard, Moglix is redefining packaging for a wide range of industries with its end-to-end sustainable packaging solutions to clients across India.

The psychology behind product packaging and brand identity

The psychology behind product packaging and brand identity

How can product packaging influence purchasing decisions? Dive into the mind of a consumer with these intriguing packaging insights.

1. Color Speaks Volumes

- Cultural Implications: Colors evoke powerful emotions. In the West, blue signifies cleanliness, leading to its use in toothpaste, cleaning solutions, and even toilet paper packaging. Red induces feelings of pleasure and is a favorite for snack packaging, while green screams health, making it ideal for natural foods.

- Context Matters: While black might be an odd choice for cereals due to its association with death, its luxury and power undertones have been harnessed effectively, as seen when Apple switched to a black design for the iPhone.

- Tailored for Target: Always remember color interpretations can vary based on culture, gender, and age.

2. Feel It with Texture

- Texture Tells Tales: Beyond just looks, the feel of a package speaks to its quality. While women’s cosmetics usually feel silky, men’s products have a rugged texture, enhancing the masculinity vibe.

- Matte Vs. Shiny: Many natural crisps brands opted for matte bags to distance themselves from unhealthy crisps, contrasting the shiny ones associated with unhealthiness.

3. The Magic of Imagery

- Strategic Images: Using vertical stripes can create a luxurious feel. Showing a filled food bowl can entice consumers to eat more, and unrelated images, like a grain field on a grain-free product, can positively influence perception.

4. Shape Matters

- Shape Associations: Angular designs, like pentagon-shaped beer bottles, exude masculinity. In contrast, rounded shapes communicate gentleness and are suitable for family desserts. Also, square packaging can intensify food taste perceptions.

- Unique Shapes: Packaging with unconventional shapes can make consumers think there’s more product inside than there is.

5. Size Does Count

- Bigger or Better: Large packaging can increase consumption—great for snacks and essentials, making customers feel they’re getting a good deal. However, smaller packaging can denote higher quality, appealing to brands wanting to convey luxury.

How Packaging Shapes Brand Identity?

Product packaging is not just a protective shell or a mere selling tool; it’s a brand’s visual voice. Here’s how packaging influences brand identity:

- Brand Expression: Quality design distinguishes leading brands, making them memorable.

- Relationship Building: User-friendly packaging fosters loyalty and can justify higher prices.

- Communication: Effective packaging clearly conveys essential product details.

- Selling: Beyond initial sales, the packaging ensures repeat business through positive user experiences.

- Protection & Aesthetics: While design attracts, functionality ensures trust.

Conclusion:

Packaging is more than just a protective barrier—it’s an intricate dance of psychology and branding. Every design element holds weight, from color choices influenced by cultural nuances to tactile experiences that resonate with target audiences. How a product is packaged can profoundly affect consumer perception, drive sales, and build lasting brand loyalty. The subtle language communicates a brand’s promise, quality, and identity, ensuring it stands out and remains memorable in a sea of choices.

Packaging and E-Commerce: Meeting the Demands of Online Shopping in a Greener Way

Packaging and E-Commerce: Meeting the Demands of Online Shopping in a Greener Way

Packaging and E-Commerce: A Green Revolution for Online Shopping

Packaging plays a pivotal role in a world where online shopping is the new norm. Did you know that over 2.14 billion people will buy online by 2021? (Source: Statista) But there’s a pressing issue we can’t ignore – the environmental impact of packaging. Let’s unravel the dynamic relationship between packaging and e-commerce while unveiling innovative strategies to meet the demands of online shopping sustainably.

The E-Commerce Wave: A Greener Path Ahead

As the digital shopping realm expands, packaging finds itself at a crossroads. Striking a balance between convenience and eco-friendliness is the challenge we tackle today.

The Packaging Puzzle: Unveiling the Dilemma

Why should you delve into this? The answer is clear: our planet’s health is at stake. The heaps of packaging waste – from plastic to cardboard – contribute to a looming environmental crisis. As consumers, we hold the power to advocate for change and steer e-commerce in a greener direction.

Innovative Packaging: Shaping Tomorrow, Today

- Smart “Right-Size” Approach: Opting for packaging that fits products snugly minimizes waste and enhances shipping efficiency.

- Eco-Materials Revolution: From recycled materials to biodegradable alternatives, businesses are embracing packaging materials that nurture, not harm, the environment.

- Less is More Philosophy: Embracing minimalist packaging not only reduces waste but also simplifies recycling processes.

The Time for Change: The Call to Action

Change isn’t a distant concept; it’s urgent. With landfills overflowing and our oceans drowning in plastic, the time for change is now. Our urgency isn’t just for today’s convenience; it’s for preserving a thriving world for generations to come.

The Data-Driven Path: Unmasking the Value

Data speaks volumes about the value of sustainable packaging. Research shows that consumers are willing to pay extra for products housed in eco-friendly packaging. (Source: Forbes) This isn’t a fleeting trend; it’s a transformative shift in consumer behavior.

Your Role: A Green Shopping Agenda

Pick Smartly: Opt for products with minimal packaging to reduce waste.

Champion Green Brands: Support businesses that prioritize eco-conscious packaging.

Spread Awareness: Educate others about the impact of packaging on our planet and encourage eco-friendly choices.

Conclusion: Packaging, E-Commerce, and a Greener Future

As e-commerce reshapes our shopping habits, let’s reshape our planet’s destiny too. Sustainable packaging isn’t just a notion; it’s a revolution in responsible consumption. With every online purchase, we cast a vote for a more sustainable future. Let’s make our choices count, ensuring that convenience and environmental consciousness go hand in hand.

Beyond Greenwashing: Authentic Strategies for Implementing Sustainable Packaging

Beyond Greenwashing: Authentic Strategies for Implementing Sustainable Packaging

Did you know that packaging accounts for 40% of the global plastic consumption? This is ironic, considering that over 70% of consumers are willing to pay for green packaging. In fact, more than one-third of people would buy additional green-packaged products if they could find them easily with clear labels.

With consumer focus shifting rapidly, your brand image could be impacted if your business still hasn’t adopted eco-packaging solutions. Continue reading to find out which trends to adopt.

Trends and Innovations in Eco-Friendly Packaging

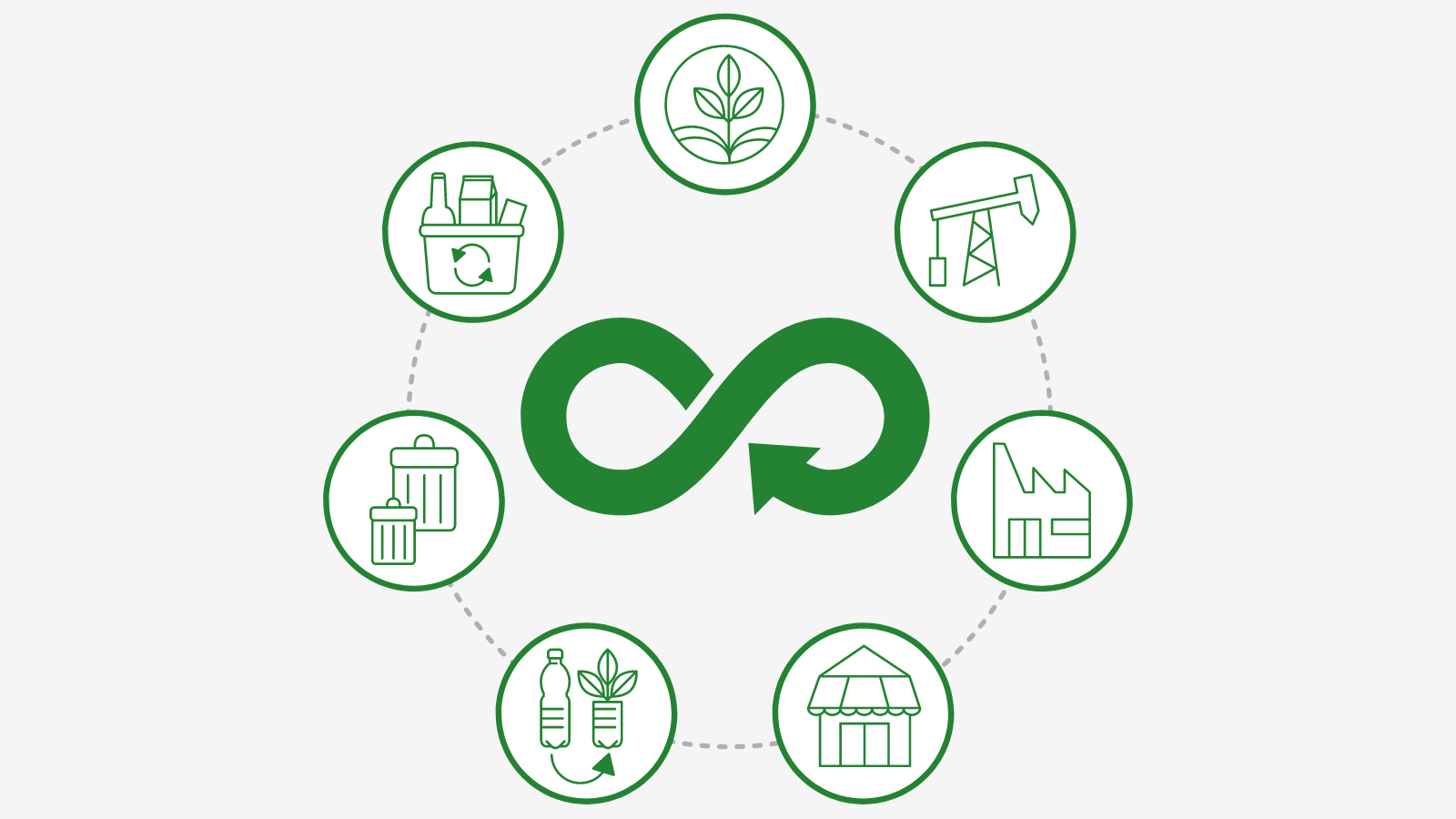

Eco-friendly packaging is a key component of a circular economy, which is a model of production and consumption geared towards waste reduction, recyclable materials, and regenerating nature.

To achieve this, your eco-packaging solutions must consider the environmental aspects of the entire life cycle of a product or service — from raw material extraction to disposal or recycling. This process is known as life-cycle assessment.

However, not all green packaging claims are trustworthy. Greenwashing can occur when you promote one sustainable stage of the life cycle but ignore another harmful stage. For example, a company may use recycled plastic for packaging but ship products using harmful modes of transportation.

So if you are a manufacturer or retailer, consider the following trends in packaging sustainability designed with the principles of circular economy and life cycle assessment.

Packaging Trends

You can achieve packaging sustainability by following these eco-packaging trends:

- Upcycling: It transforms used products into new sustainable materials or products with more value than the original ones. For example, upcycling a tire into a coffee table.

- Sustainable sourcing: It involves selecting environmentally-conscious suppliers and renewable or remanufactured materials. Begin implementing sustainable sourcing by communicating your sustainability goals to suppliers.

- Green Logistics: Integrating environmental considerations into logistics minimizes their ecological impact and maximizes efficiency. Companies can implement green logistics using green transportation, sustainable materials, and energy-efficient factory practices.

Packaging Material

To keep up with changing consumer demands and environmental challenges, here are some packaging innovations you can adopt:

- Convert fibers from fishing nets and ropes into high-grade plastic to package products or to make bottles.

- Water soluble packaging for high-quality eco-friendly garment bags.

- Seaweed is another sustainable packaging innovation for making food takeaway containers.

Packaging Design

Here are some sustainable design trends for packaging coveted by consumers:

- Use plant-based dyes to create a safe and environmentally-friendly look for your package design.

- Using reusable or refillable packaging — like fabric bags — promotes waste reduction and decreases carbon footprint.

- Minimalist package design is a sustainable design option that reduces space during transportation, reducing your carbon footprint.

Click here to learn more about how Moglix can help you implement sustainable packaging in the supply chain.

Optimizing Packaging Operations: Strategies for Achieving Operational Efficiency

Optimizing Packaging Operations: Strategies for Achieving Operational Efficiency

Did you know the global packaging industry is estimated to grow over $80 billion by 2023? Packaging operations are essential to any industry and manufacturing or distribution process. Optimized packaging operations involve improving the efficiency and effectiveness of the operations by eliminating waste, reducing costs, increasing output, and improving quality.

But process optimization for packing operations is not just about ensuring proper packaging equipment and machinery. It is also about designing and implementing efficient packaging strategies and continuously optimizing them to reduce costs and increase efficiency and output. How? Continue reading to find out.

Strategies to Achieve Packaging Efficiency

1. Automation and technology

In Q1–2022, companies in the US, Canada, and Mexico increased usage of industrial robots by nearly 30% and the robotics industry experienced a 40% surge in revenue. One of the major reasons is that automation and technology usage can increase efficiency by speeding up the packaging processes. It can help you save time and money by reducing the need for human intervention — while improving packaging quality and consistency.

2. Supply Chain Integration

Supply chain integration can help you streamline processes and improve customer service by smoothing out communication. It can improve collaboration within parts of the supply chain, making it easier to troubleshoot issues. A seamless integration with the supply chain enhances the visibility of varying packaging stages and improves cooperation and risk management.

3. Standardization and Modular Design

Standardization means using standardized components for different products or purposes. Modular design, conversely, means dividing a complex product into smaller units that can be easily assembled and disassembled.

Standardization and modular design can help you make products easily, make repairs easy, reduce waste, and optimize resource consumption. It can also improve productivity and profitability.

4. Inventory Management

Inventory management can help businesses minimize the cost of inventory by helping them reduce warehouse space, avoiding label stock-outs, and improving supplier relations. An inventory management software can use your historical data to forecast demand and align your production and delivery processes around anticipated packaging needs. Over time, all of these factors can impact your bottomline.

5. Quality Control and Testing

Quality control and testing in packQuality Control and Testingaging operations are processes used to ensure that packaging methods and materials are suitable, safe, and comply with industry standards. Proper control and testing can help you optimize a package by helping you prevent or minimize the risk of product damage, contamination, leakage, or loss during transport.

It can also ensure that your product has adequate protection, presentation, and information for the consumer. This way, it can improve the efficiency of your packaging operations by reducing waste, rework, recalls, and complaints.

Moglix makes process optimization for packaging operations easy by going over and beyond the packaging equipment and machinery; click here to find out how.

Future forecast: 3 trends in interactive packaging that could be the new normal in 2023

Future forecast: 3 trends in interactive packaging that could be the new normal in 2023

Three trends that could define interactive packaging in 2023 and beyond

When it comes to packaging today, attractive and informative no longer suffice. Instead, interactive packaging could be the new benchmark for leaders in the packaging industry to pursue. Designed to create consumer engagement in one way or the other, interactive packaging creates a deeper connection between the customer and your brand. It can be through technology, such as QR codes or augmented reality features, or through more conventional channels, like packaging that includes games or puzzles.Here are some popular types of interactive design that could revolutionize packaging across the F&B, electronics and even the cosmetics industry in 2023 and the years that follow.

Technology-based interactive packaging:

Technology can be used in packaging to create an interactive experience for the consumer. Popular examples of this kind of design include touchscreens, QR codes, and even augmented reality on the package. Plant-based snack company Mezcla excelled at this type of packaging when it included a QR code on the package. Customers could scan the code to view artwork submitted by others worldwide and even submit their own.

Game-based interactive packaging:

Gamification is also succeeding at delighting customers and transforming packaging today. This type of packaging includes games or puzzles that the consumer can solve or play as part of the packaging experience. India’s most popular jam, Kissan, chose this route when it included a kid-friendly board game as a part of its jam packaging.

Customizable packaging:

This packaging allows the consumer to personalize the packaging by adding their own artwork or photos. Kokoa Hut put a brilliant spin on this idea by offering bags that buyers could customize. The bags contained tiny square boxes that could be flipped upward to create distinct images or text. Customers could play around with this feature and create custom texts like their name or a symbol like a heart or a star on their bags.

Future focus: Is interactive packaging the future?

Packaging now matters almost as much as the product, and in the coming years, the rise of interactive packaging as a preferred alternative to traditional options is perhaps inevitable. As a bonus, interactive packaging can be used for various products, including food, cosmetics, and consumer electronics.

Further, interactive and intelligent packing opens up a new avenue for successful customer engagement, which can be a fun and novel experience for the end user. Positive interactions like this can improve your top line because research reveals that around 72% of customers share good brand engagement and experiences with at least six others.

Want to stay ahead of the curve? A competent packaging solutions provider can help.

With the packaging industry’s landscape changing dynamically and supporting new trends in recent years, it is crucial to have a competitive edge today. Give your business the advantage it deserves by partnering with a comprehensive packaging solutions provider like Moglix. We offer extensive services in this domain, including vendor and inventory management, quality control and compliance and primary, secondary as well as tertiary packaging solutions. Visit our website to learn more.

A closer look at corrugated box packaging: And why it is the future of a circular economy

A closer look at corrugated box packaging: And why it is the future of a circular economy

Why corrugated boxes fit perfectly into the narrative of a circular economy

The American Forest & Paper Association had some encouraging news to report last year; a colossal 91.4% of old corrugated containers (OCCs) were recycled in the U.S. in 2021. Also, corrugated packaging ranks among the most recyclable options elsewhere in the world. This makes it a natural choice to pursue a circular economy, where resources are used, reused, and recycled in a closed loop — thus preserving natural resources and minimizing waste and pollution.

But even beyond their recyclability alone, corrugated boxes are the ultimate expression of a circular economy because they are sustainable across the product life cycle, from manufacture to recycling. Here’s how.

Manufacture and production

Life cycle assessment reports reveal that corrugated box manufacturers in the U.S. have been increasingly switching to renewable energy sources and simultaneously reducing greenhouse gas emissions. Elsewhere in the world, too, corrugated box production is highly sustainable, and with good manufacturing practices we can get good strength with higher percentage of recycled content.

Even in the regions that rely on fossil fuels for box manufacture, it can be relatively easy to make the transition to green energy sources that are also highly sustainable. This makes corrugated packaging a distinct example of circularity at the production stage.

Supply chain sustainability

Throughout its product life cycle, corrugated packaging is an integral part of the supply chain in various industries across the globe. From food and beverages, e-commerce, and office supplies to more sensitive products like electronics and healthcare equipment, corrugated boxes are perfectly suited to house many goods.

Sustainability is one of the key reasons driving the popularity of this packaging material. This, coupled with other valuable characteristics like rigidity, customizability, and scalability, only strengthens the case for circularity in corrugated packaging.

Reuse and recycling

Among the most recycled materials on the planet, corrugated boxes remain sustainable even toward the end of their usable life cycle. However, this is an area that requires a fair bit of streamlining, mainly when the boxes are used in last-mile delivery.

Since many end users are unaware of the high recyclability quotient of corrugated boxes, the cartons are often misdirected to landfills and other wastelands, pulling down the overall percentage of packages that can be put back into circulation. Awareness programs and conscientiousness among end users can reverse this situation and further improve the impressive role of corrugated boxes in a circular economy.

Want to give your business an advantage in the race to circularity?

Making the switch to corrugated box packaging or other recyclable packaging wherever possible could be a great place to begin. Moglix can be your ally in this challenging yet crucial transformation to sustainable solutions. Our end-to-end packaging procurement solutions can make the journey to circularity easier and quicker for you. Visit our website to learn more.