Top 10 Garbage Bags Manufacturers In India 2026: Small, Medium, And Large Garbage Bags With Prices And Features

Top 10 Garbage Bags Manufacturers In India 2026: Small, Medium, And Large Garbage Bags With Prices And Features

Garbage bags, whether referred to as dustbin bags, trash bags, bin liners, or garbage sack liners, are essential for hygienic and efficient waste management in homes, offices, industries, hospitals, and public spaces. In India’s growing market for sustainable and everyday utility products, many manufacturers now offer a broad range of products, including biodegradable garbage bags, high-strength plastic bags, and eco-friendly trash bags of various sizes.

Businesses, industries, and retailers seek for top quality trash and garbage bags based on their requirements. If you are also looking to buy garbage bags in bulk, then Moglix is the one-stop destination to procure them efficiently. We offer you a wide range of dustbin bags to trash bags of different sizes, with a customized option to fulfill every specific requirement. Therefore, this blog dives into the top 10 garbage bag manufacturers in India (2026), along with their popular products, key features, approximate price ranges, and what makes them stand out.

What Are The Various Types Of Garbage Bags?

Knowing every specific type of garbage bag is important to find the right product based on the project requirement.

- Standard Plastic Garbage Bags

Made from LDPE or HDPE material, these are the most commonly used dustbin bags for homes, offices, and commercial spaces. They are cost-effective, lightweight, and suitable for dry and mixed waste. - Biodegradable Garbage Bags

These bags are manufactured using plant-based or compostable materials and are designed to decompose faster than regular plastic. Biodegradable garbage bags are ideal for eco-conscious households and organizations focusing on sustainable waste management. - Compostable Trash Bags

A sub-category of biodegradable bags, compostable trash bags break down completely into natural elements under composting conditions, making them suitable for organic and wet waste disposal. - Scented Garbage Bags

These trash bags come with fragrance additives to help control unpleasant odors, making them suitable for indoor bins and food waste disposal areas. - Recycled Plastic Garbage Bags

Manufactured using post-consumer recycled plastic, these bags help reduce plastic waste while offering reliable strength for everyday garbage collection. - Color-Coded Garbage Bags

Used for waste segregation, different colors indicate dry waste, wet waste, biomedical waste, or hazardous waste, commonly used in hospitals and municipalities.

Check Out The List Of The Top 10 Garbage Bags In India 2026

Based on peer reviews, quality of products, extensive catalog, and overall sales, we have curated the list of the top 10 trash garbage bags manufacturers you can opt for. Let’s have a quick look at them:

1. Greendot Biopak Pvt. Ltd. – Eco & Compostable Garbage Bags

A leading Indian manufacturer specializing in biodegradable garbage bags that are eco-friendly alternatives to traditional plastic bags. Their products are made from plant-based materials and designed to break down naturally over time.

Key Features:

- Compostable and biodegradable materials (plant-based)

- Leak-proof, tear-resistant, and durable

- Suitable for wet and dry waste

- Ideal for homes, offices, hospitality, and public bins

- Multi-size options available

Typical Price: Rs. 180–Rs. 350/kg depending on size/material

Best For: Environment-friendly disposal, green waste bins

2. Sri Krishna Polymers – Comprehensive Garbage Bag Range

A well-established Indian manufacturer offering a wide portfolio of garbage bags, including biodegradable trash bags, plastic dustbin bags, eco options, and clinical waste bags.

Key Features:

- HDPE and LDPE options (plastic & biodegradable)

- Custom sizes and thicknesses

- Dustbin covers for small to large bins

- Disposable, eco, biohazard, and compostable bags

Typical Price: Rs. 80–Rs. 200/kg (varies by product type)

Best For: General household waste, commercial trash bags

3. Murth – CPCB-Certified Biodegradable Dustbin Bags

An Indian brand known for CPCB-certified biodegradable garbage bags made from plant-based biopolymers, suited for households and commercial usage.

Key Features:

- 100% compostable and biodegradable

- CPCB & IS/ISO standards compliance

- Leak-proof and tear-resistant

- Varied sizes, including small, medium, and large

- Breaks down in 60–180 days

Typical Price Range: Rs. 250–Rs. 360/kg

Best For: Eco-conscious users and institutional waste management

4. Arihant Industries India – Dustbin & Trash Bag Manufacturer

A manufacturer offering standard and biodegradable garbage bags, including heavy-duty trash bags and dustbin liners.

Key Features:

- Standard plastic garbage bags (various sizes)

- Biodegradable options available

- Heavy-duty and biohazard variants

- On-roll and flat pack formats

Typical Price: Rs. 15–Rs. 30 per piece (varies by type & size)

Best For: Bulk needs, industrial waste, and daily dustbin use

5. Allied Propack Pvt. Ltd. – Recycled & Dustbin Bags

Listed among India’s reliable recycled garbage bag manufacturers, offering various sustainable and recycled trash bag solutions.

Key Features:

- Recycled plastic bags mitigate environmental impact

- Variety of sizes and capacities

- Suitable for everyday waste disposal

Typical Price: Competitive (varies by bulk orders)

Best For: Eco-friendly recycled options and budget buyers

6. Valor Industries – Recycled & Garbage Bag Supplier

Part of the top recycled trash bags suppliers in India, with a range of dustbin bags produced from recycled plastics.

Key Features:

- Recycled plastic waste bag range

- Strong and tear-resistant

- Available to bulk customers

Typical Price: Varies by material and weight

Best For: Commercial, household, and eco-conscious customers

7. Velox Hygiene Products LLP – Waste Bags

Another notable manufacturer of recycled and biodegradable garbage bags is especially for commercial and household waste collection.

Key Features:

- Focus on hygiene and durable performance

- Sizes from small household liners to large trash bags

- Eco-oriented recycled products

Typical Price: Market competitive

Best For: Businesses and institutional waste management

8. Eco365 – Compostable Garbage Bag Brand

A popular seller of 100% compostable and biodegradable trash bags in India, made from plant extracts and designed to meet environmental standards.

Key Features:

- Certified biodegradable, non-plastic bags

- Compostable in natural conditions

- Available in small to medium pack sizes

Typical Price: Rs. 190–Rs. 300 per pack (size dependent)

Best For: Home composters and eco-focused households

9. Shakthi Enterprises – Durable Biodegradable Garbage Bags

Manufacturers focused on producing biodegradable and eco-friendly dustbin bags that are strong and tear-resistant.

Key Features:

- Biodegradable materials

- Leak-proof and tough design

- Multiple size formats

Typical Price: Varies (depending on size and material grade)

Best For: Everyday and medium–heavy use waste disposal

10. Clean India Biodegradable Garbage Bag Range

Although not a single manufacturer brand, Clean India’s biodegradable trash bags are widely used eco-bags from various suppliers across India, notable for affordability and growth in demand.

Key Features:

- Biodegradable material

- Leak-proof and durable

- Medium to large dustbin sizes

- Affordable price

Typical Price: Rs. 36 for 15 bags (medium)

Best For: Daily home and light commercial use

Quick look at the Garbage Bags Buying Guide (2026)

Based on Sizes & Uses

- Small Garbage Bags (Drawstring/Small Dustbin Bags): Best for bathroom bins, bedrooms – typically 8–15 L capacity.

- Medium Trash Bags: Ideal for kitchen waste or office bins – around 20–35 L.

- Large Garbage Bags: For outdoor bins, commercial kitchens, and event clean-up – 50–90+ L.

Biodegradable vs. Traditional Plastic Bags

- Traditional Plastic Bags: Cheaper, stronger, but take hundreds of years to degrade.

- Biodegradable Garbage Bags: Break down faster under proper conditions; much better for the environment.

- Important to choose CPCB/ISO-certified compostable bags for proper waste segregation and compliance.

Key Features to Consider

Leak-proof & Tear-resistant: Prevent messy spills.

Drawstring or Tie Closure: Helps secure waste easily.

Capacity & Thickness: Thick gauge for heavy waste.

Eco Certifications: CPCB/ISO standards ensure actual biodegradability.

Final Thoughts

Whether you’re stocking up for home kitchens, corporate offices, industrial facilities, hospitals, or public waste management programs, India’s garbage bag manufacturing ecosystem in 2026 offers durable, eco-friendly, and affordable options. Choosing the right brand, from everyday dustbin bags to advanced biodegradable garbage bags, not only simplifies waste disposal but also supports cleaner cities and sustainable living.

However, if you are looking for bulk procurement of garbage bags from top and trustworthy suppliers and manufacturers, Packaging Moglix is the one-stop online platform for effective and hassle-free purchase. You can easily raiase RFQ based on your requirement and get delivered over pan India.

Top 10 Paper Bag Manufacturers in India 2026: Types, Prices, And Features to Look For

Top 10 Paper Bag Manufacturers in India 2026: Types, Prices, And Features to Look For

The continuous focus on sustainability has evoked the usage of paper bags, becoming the priority for many businesses to utilize sustainable materials and replace plastic across various retail, gifting, e-commerce, and food services. Not only in India, but also the global organizations are spreading awareness to eliminate plastic, while focusing on sustainable materials like paper bags, to expand rapidly. Therefore, enterprises and businesses looking to procure kraft paper bags, white paper bags, custom paper bags, printed paper bags, small paper bags, brown paper bags, paper carrier bags, etc., can partner with Moglix and procure them seamlessly in bulk.

However, for your better understanding, we have provided you with a complete guide on the top 10 paper bag suppliers in India 2026. Let’s have a quick look at the complete list.

Importance of Paper Bags in 2026

The importance of Paper bags cannot be overlooked in recent period. They are known for

- Best eco-friendly and biodegradable packaging solution

- Provide decent durability with a stylish look and available in printed option

- Can be utilized across various sectors, from the grocery business to luxury retail.

- Cost-efficient with a bulk pricing option

Types of Paper Bags Common in India

Here are the main types you’ll find:

| Type | Description | Typical Price Range (India) |

| Kraft Paper Bags | Strong, recycled, everyday use | ₹10–₹30 |

| Brown Paper Bags | Natural look, sturdy | ₹15–₹35 |

| Printed Bags | Custom brand logos and designs | ₹20–₹50 |

| Shopping Bags | Reinforced handles for retail | ₹25–₹60 |

| Luxury Paper Bags | Premium finish, gifting | ₹50–₹150 |

Top 10 Paper Bag Manufacturers in India (2026)

We have curated the list of top 10 paper bag manufacturers in India for 2026 based on recent developments, product range, peer reviews, customization option and reputation.

OLIVIA INTERNATIONAL

One of the most reputed and well-known brands for providing value pricing and quality paper kraft bags. It is an excellent choice for beginners, startups, or small retailers. They offer a complete range of paper bags with customization options and a low minimum order quantity.

Best for: Small businesses, Low pricing, Standard retail bags

CONIFER HANDMADES

One of the most highly rated paper bag suppliers, offering premium quality and a wide range of sustainable bags at the best prices. The strong and positive reviews over time showcases theur experience and powerful brand in packaging solution providers.

Best for: Premium gifting bags, Custom print, Boutique brands

FLYMAX EXIM

The brand mostly focuses on designing durable, attractive, and FSC-certified bags. They have been setting the trends with amazing, strong, and appealing designs in their paper bags.

Best for: Branded retail packaging, Recyclable bags

TAJ PAPER UDYOG

It is also one of the most standard brands offering the best and most robust custom paper bags. What makes them outstanding is the customization and printing options.

Best for: Custom projects, Mid-tier orders

BIZCOVERINDIA.COM LLP

One of the most efficient and verified paper bag suppliers with a humongous production space. The band ofes a larger projects and bulk contracts at a single time.

Best for: Bulk orders, B2B clients

ECOREV

The brand offers effective, recyclable, and eco-friendly paper bags with amazing and robust quality. It offers a wide range of products for sustainability and quality at the top.

Best for: Eco-conscious brands, Mid-sized orders

VISION GLOBAL EXPORT

Reliable manufacturer offering multi-size bags with custom printing at competitive prices. Good option for retailers and small exporters.

Best for: Retail & export orders

FARHANCRYSTAL

Known for biodegradable, food-grade bags, especially for restaurants and QSR chains. Offers competitive price points.

Best for: Food & beverage packaging

Dutta Enterprise

A seasoned manufacturer with experience in biodegradable and custom printed bags, including duplex and jewelry bags.

Best for: Custom orders, Diverse bag types

Pilani Udyog

Operating since the ’90s, this company has made a wide range of paper bags and accessories, including SOS bags and envelopes. Good logistics support.

Best for: Diverse product range, Large B2B clients

Paper bag indicative Pricing in 2026

Pricing depends on:

- Material quality (GSM)

- Handles (twisted rope, ribbon, reinforced)

- Print (single color vs CMYK/Pantone)

- Order quantity & customization

Typical wholesale ranges in India:

- Basic Kraft (no print): ₹2.50–₹6 per piece

- Printed Paper Bags: ₹6–₹15 per piece

- Laminated/Gift Bags: ₹10–₹30+ per piece (premium)

Key Features to Look for Before Buying Paper Bags

Choosing the right manufacturer is more than just pricing. Here’s what to consider:

- Material Quality: Never compromise on the quality of materials used in the manufacturing of paper bags. You can look for high GSM kraft and recycled paper for better strength and quality.

- Handle & Usability: Check the design and features like paper nag with handles for better usability. It offers comfort and better load support.

- Print Quality: If you are focusing on better brand visibility, then do not compromise on the print quality on paper bags. Always choose brands that offer high-resolution CMYK printing and logo design with other customization options.

- Eco Certification: Prioritize the FSC, ISO 9001, or sustainability credentials that show credible practices.

- MOQ & Lead Time: Check minimum order quantity and delivery timelines before ordering.

Conclusion

Paper bags are known as a reliable packaging solution for sustainability and branding. No matter whether you are a small business, industry, or enterprise, paper bags have spread their horizons in every sector. In 2026, the demand is rising, and many sectors are opting for paper kraft bags to deliver powerful messages, braiding, and eco-friendly options towards the growth of business and the environment, too. However, if you are looking for a one-stop destination and online platform to buy paper bags at the most affordable price, you can partner with Moglix Packaging.

Top 10 Packaging Companies in India 2026: Types, Prices And Features to Look For

Top 10 Packaging Companies in India 2026: Types, Prices And Features to Look For

As we are heading towards rapid industrial growth, the packaging process and transformation cannot be neglected in driving the success of industries. The emergence and significance of packaging materials play a pivotal role in the growth of e-commerce, FMCG, pharmaceutical, and global export opportunities. Even the progressive approach towards sustainable packaging has changed the business game. Therefore, every business and industry prioritizes the right type of packaging for products from various trusted and reputable brands. Keeping its importance at peak, we have collected the latest data for the top 10 packaging companies in India (2026), offering complete packaging solutions. However, if you are looking to buy packaging materials in bulk, then Moglix is the one-stop destination to procure them seamlessly. With this guide, you will be able to find the best packaging companies suitable for your products and analyze the pricing expectation, their offering, and key features that meet your packaging requirements.

Why Packaging Matters in 2026?

Packaging has become an influential, sustainable, and eye-appealing aspect for many industries, especially products like personal care, logistics, food and beverage, and pharmaceutical. Therefore, businesses want to stand out in every segment of their product efficiency, while focusing on below listed factors:

- Sustainability & recyclability

- Cost efficiency

- Durability & protection

- Compliance with food/ pharma safety standards

- Brand appeal & customization

We’ll cover both industry leaders and what makes them stand out in 2026.

Check Out the Complete List of Top 10 Packaging Companies In India (2026)

If you are also among those businesses and industries looking to procure the best packaging materials from reliable sources, then Moglix is the one-stop destination to avail them seamlessly. We have provided you with the list of the best packaging brands you can rely on.

1. Uflex Ltd.

One of the highly rated and renowned packaging companies, Uflex Ltd, offers a complete and flexible packaging solution around the globe. They ensure the procurement of packaging solutions like printed films, flexible pouches, and high-barrier laminates for food items, covering the entire FMCG and medical sectors. The price range of their packaging material falls between ₹6–₹12 per unit, and printed films range between ₹150–₹300 per kg. The company is well known for providing ISO and FDA-certified and sustainable packaging solutions.

2. Essel Propack Ltd. (EPL)

Essel Propack Ltd., also known as EPL, is a reputed brand based in Mumbai offering top-quality laminated tube packaging solutions. The company has been serving industries like cosmetics, pharmaceuticals, and personal care. The price of their packaging materials falls between ₹5–₹30 per piece, depending on the size and printing requirement.

3. TCPL Packaging Ltd.

TPCl is a leading manufacturer in the segment of packaging material, specializing in cartons and cardboard solutions. The company has been serving major sectors like liquor, FMCG, and pharmaceuticals, offering a wide range of packaging solutions. The folding or coagulated cartons cost between Rs 8 to 40 per piece, based on design and size requirement.

4. Jindal Poly Films Ltd.

Headquartered in Nashik, Jindal Poly Films Ltd. is a major producer of polyester and polypropylene films used in flexible and specialty packaging. Its product portfolio includes BOPP, PET, and CPP films widely used across food, consumer goods, and industrial applications. Film prices generally range from ₹120–₹260 per kg. The company benefits from a backward-integrated supply chain and ongoing capacity expansion driven by recent investments.

5. Huhtamaki PPL Ltd.

This packaging company has wide horizons in the global market, specializing in overall packaging solutions. The company’s objective is to fulfill the primary packaging and labeling for various industries like Food and beverage, Pharmaceutical, and personal care brands. They have a diverse range of products for various premium to mid segments, typically priced between ₹7–₹20 per piece.

6. Polyplex Corporation Ltd.

Polyplex Corporation is a Noida-based firm and a leading manufacturer of packaging solutions, offering BoPET polyester films. The company mostly focuses on electrical insulation packaging solutions and industrial equipment packaging. The price of their products falls between ₹150–₹300 per kg.

7. Manjushree Technopack Ltd.

Manjushree Technopack Ltd. is a Bangalore-based firm and a prominent player in the manufacturing of packaging materials. They have been supplying a wide range of packaging materials, such as PET, HDPE, PP bottles and containers to FMCG groups, dairy industries, and pharmaceutical industries. The container price range falls between ₹10–₹50 per unit. They are well known for customization options according to the project requirements.

8. Cosmo Films Ltd.

Cosmo Film Ltd is a Delhi-based packaging material manufacturing company for specialty films and BOPP. They are widely known for lamination and flexible packaging solutions across various markets. Their products usually fall between ₹140–₹280 per kg.

9. Balmer Lawrie & Co. Ltd.

Balmer Lawrie & Co. Ltd. is a leading, reputable, and long-established packaging solution manufacturer offering multi-material packaging and covering a large segment of industries continuously for many years. They offer a wide range of packaging materials like barrels, large containers, and heavy-duty sustainable packaging for various industries and sectors. Their industrial packaging products typically start from ₹1,000 per unit and above.

10. Parksons Packaging

Parksons Packaging is an India-based company known for carton and specialty packaging solutions. It serves retail, FMCG, and luxury product segments with a strong focus on visual appeal and innovation. Customized cartons and packaging solutions generally range from ₹10–₹50 or more per unit. Parksons stands out for its design-centric approach and increasing use of sustainable packaging materials.

Types of Packaging & Applications

It is necessary to understand types sof packaging solutions provided by above above-listed brands and companies.

| Packaging Type | Common Uses |

| Flexible films & pouches | Snacks, beverages, and pharmaceuticals |

| Laminated tubes | Toothpaste, cosmetics, creams |

| Folding cartons | Liquor, pharma, retail boxes |

| Rigid plastic containers | Bottles for liquids, chemicals |

| Polyester/BOPP films | Labeling, lamination, barrier packaging |

Features to Look for When Choosing a Packaging Company

1. Material & Quality

- Barrier properties (oxygen/moisture resistance)

- Food-grade certifications (FDA, ISO)

2. Sustainability

- Recyclable or biodegradable materials

- EPR (Extended Producer Responsibility) compliance

3. Customization & Design

- Print quality & graphics

- Shapes, sizes, and structural design

4. Cost & Scale

- Competitive pricing

- Minimum order quantity (MOQs)

5. Delivery & Support

- Lead times and logistics reliability

- Technical support and R&D partnership

Typical Price Considerations (2026)

Pricing varies widely based on material, print quality, volume, and customization:

| Packaging Type | Approx. Price |

| Flexible pouches | ₹6–₹12 per pouch |

| Printed films | ₹150–₹300 per kg |

| Laminated tubes | ₹5–₹30 per tube |

| Cartons | ₹8–₹50 per piece |

| Plastic bottles | ₹10–₹50+ |

Final Thoughts

India’s packaging landscape in 2026 balances innovation, cost-efficiency, and sustainability. Whether you’re sourcing flexible packaging for food products, premium cartons for retail goods, or industrial containers for liquids or chemicals, there’s a top-tier company to match your needs. However, if you are looking to procure packaging materials and solutions in bulk, Moglix is the right platform to purchase them efficiently. Moglix ensures the procurement of primary, secondary, tertiary, and sustainable packaging at the most competitive prices from reputed and reliable brands, delivering to thousands of pin codes across India.

Why You Should Buy Packaging Material Wholesale Online: A Complete Guide for Smart Businesses

Why You Should Buy Packaging Material Wholesale Online: A Complete Guide for Smart Businesses

In today’s fast-paced supply chain and e-commerce environment, high-quality packaging materials aren’t optional; they’re essential. Whether you run a manufacturing unit, operate a retail shop, ship products daily, or manage a warehouse, the right packaging ensures product safety, reduces transit damage, and enhances your brand’s reputation.

Buying packaging materials wholesale online from trusted platforms like Moglix Packaging (packaging.moglix.com) has become the preferred choice for businesses of all sizes. Here’s an in-depth look at why online wholesale purchasing is a game-changer and how you can choose the right packaging products for your needs.

Top Reasons to Buy Packaging Material Wholesale Online

1. Wide Range of Packaging Products Under One Roof

Online wholesale platforms offer an unmatched variety of packaging items. Instead of relying on multiple offline suppliers, you get everything in one place, including:

- Corrugated boxes

- Bubble wrap & protective packaging

- Stretch film & shrink film

- Tapes and adhesives

- Courier bags & poly mailers

- Strapping & bundling materials

- Pallets & pallet accessories

- Industrial packaging materials

- Custom packaging solutions

This helps businesses streamline procurement and save valuable time.

2. Lower Prices with Wholesale Buying

Buying in bulk directly reduces per-unit cost.

Online platforms cut out middlemen and provide:

- Bulk discounts

- Seasonal offers

- GST invoicing

- Additional savings through subscription or repeat orders

It’s one of the most effective ways to reduce packaging expenses without compromising quality.

3. Superior Quality & Standardized Products

Reliable online suppliers follow strict quality standards. When you buy online:

- You receive consistent product quality

- Every batch matches the same specifications

- Defective and low-quality material is minimized

For businesses shipping regularly, this consistency is crucial.

4. Easy Comparison & Better Decision Making

Offline buying doesn’t allow easy comparison. Online platforms show:

- Detailed product specifications

- Customer reviews

- Technical sheets

- Price comparison across brands

This makes choosing the right packaging material easier and more transparent.

5. Quick Delivery Across India

Platforms like Moglix Packaging offer fast and reliable delivery. You receive packaging stock on time whether for daily dispatch operations or emergency restocking.

Types of Packaging Materials You Can Buy Online

Here’s a quick overview of popular packaging materials available on Moglix Packaging:

1. Corrugated Boxes

- 3-ply, 5-ply, and 7-ply cartons

- Custom-sized boxes

- Heavy-duty boxes for industrial shipping

Ideal for e-commerce shipments, fragile goods, and bulk packaging.

2. Protective Packaging

- Bubble wrap rolls

- Air pillows

- Foam sheets

- Thermocol (EPS) sheets

These materials keep delicate products safe during transit.

3. Tapes and Adhesives

- BOPP packing tape

- Masking tape

- Industrial adhesive solutions

- Dispensers and tape guns

Quality tape ensures secure packing and reduces tampering risks.

4. Stretch Film & Shrink Wrap

Used widely in warehouses to bundle, wrap, or secure pallets.

Available in multiple thicknesses and roll sizes.

5. Poly Mailers & Courier Bags

Tamper-proof packaging for e-commerce and courier shipments such as:

- POD jacket bags

- Tamper-evident courier pouches

- Bubble mailers

6. Strapping & Bundling Materials

- PP strapping rolls

- PET straps

- Buckles & sealers

- Strapping machines (semi-auto/automatic)

Perfect for heavy-duty packaging in manufacturing units.

How to Choose the Right Packaging Material (Buying Guide)

1. Identify Your Packaging Needs

Ask yourself:

- What products are you shipping?

- Are they fragile, heavy, or unusual in shape?

- How far are they shipped?

This helps determine whether you need lightweight packaging or heavy-duty materials.

2. Choose the Correct Load Type

- Light load: Courier bags, 3-ply boxes, small bubble wrap

- Medium load: 5-ply boxes, stretch films, PET straps

- Heavy load: 7-ply boxes, wooden pallets, industrial straps

3. Prioritize Protective Packaging

If your products are delicate, invest in:

- Bubble wrap

- Foam rolls

- Air cushions

This reduces returns and customer complaints.

4. Check Product Specifications Carefully

Before you buy, verify:

- GSM or thickness of materials

- Ply count for boxes

- Length/width of rolls

- Tensile strength for straps

Minor differences in specs can significantly affect protection and durability.

5. Look for Trusted Online Platforms

Choose suppliers known for quality, service, and reliability.

Moglix Packaging offers:

- Trusted brands

- Verified sellers

- GST billing

- Easy returns

- Bulk pricing

This ensures peace of mind and long-term savings.

Conclusion

Buying packaging material wholesale online is no longer just a budget-friendly option—it’s a strategic upgrade for businesses looking to improve efficiency, reduce costs, and access a complete range of packaging supplies in one place. Platforms like packaging.moglix.com provide high-quality, affordable, and reliable packaging solutions with fast delivery across India

Cut Food-Grade Packaging Costs in 2025-Without Sacrificing Quality

Cut Food-Grade Packaging Costs in 2025-Without Sacrificing Quality

Food packaging does not stop at a box

The reality is, the food packaging aspect of a product hasn’t always been the most invigorating section of the product. People would just take a product, a box, or a bag, seal it, and ship it, and that would be the end of that. But now? Packaging is much more than just a casing. It’s an integral element of the brand narrative, as well as a necessary protective measure for the product, and of course, it impacts profits as well.

Just to see, it is amusing that many companies manage to not get noticed while slashing 10 to 12% off their packaging budgets. That’s right! No flimsy plastic bags. No weak seals. Just a combination of more intelligent packaging choices.

So, what’s their secret sauce? It’s not cutting corners. It’s about picking the right materials. What do you think their secret is? No, it’s not that they pinch pennies here and there. It’s a combination of selecting the right materials, optimizing the designs, and establishing reliable contracts with the vendors. Let’s explore this a little more.

What Does Food-Grade Packaging Mean?

Simply put, food-grade means there are no chemicals that can leach in, no odd tastes, and no other concerns. There are always regulations, like the FDA and EFSA, but the principles remain universal in that food should be kept fresh, protected, and delicious.

Not doing this step? Mistake. Reputational damage, in conjunction with unsatisfied clients and product recalls, could be the end result.

The Main Players in Food-Grade Packaging

- Corrugated Cardboard: Keeps dry foods as well as fresh produce. Corrugated Cardboard is secondary-usable, strong, and a lot of companies use fibers with water-resistant coatings that come from recycled materials.

- Plastic Films and Poly Bags: The green alternatives that are more and more common, and are perfect for snacks, frozen foods, and anything needing moisture protection.

- Paper and Kraft Bags: Always used for fresh produce and bakery items, but should be moisture and grease-resistant.

- Glass and Metal Containers: The best and most popular for canned items, sauces, and various beverages. It can also be relatively expensive and heavy for transport due to the light and air resistance.

- Biodegradable Materials: These are the most recent materials used; they are eco-friendly, but be cautious of price and durability.

Other Considerations While Selecting Packaging

- Safety Comes First: Don’t be vague; food safety is a matter for the defense.

- Fit for Your Food: Based on the moisture and fragility of the food, and even whether it is fresh or frozen, the type of packaging shall vary.

- Green is Great If It Works: If the packaging does not overly charge, and retains the food well, then the sustainability of it is a big plus.

- Think Beyond Price: What, on the surface, looks like a low-cost option could lead to excess importation, excessive waste, and spoilage.

How Smart Companies Win at Food Packaging

- Test Samples Before You Commit: It is incorrect to believe that packaging is functional and will yield the desired results without being tested.

- Think Whole Package: All of it is important. If one of the components of the offer, the seals, the distractions, the covers, the inscriptions, the adhesives, or the interliners is weak, then the entire package could be destroyed.

- Choose Partners Wisely: Suppliers who offer constructive and supportive collaboration are very important.

- Keep Your Packaging Fresh: Don’t put it on autopilot. If new alternatives or modern approaches to packaging are not analyzed and revised on a constant basis, then profit will be lost.

Why Good Packaging Pays Off

Good packaging will lead to a decrease in the return of the product, decrease food that goes to waste, and increase the amount of satisfied and retained customers. If done correctly, it allows one to use it as a competitive advantage as opposed to being solely burdened with the cost.

Practical Tips That Actually Work

- Review Packaging Often

Touching the packaging once and not coming back to it is not the answer. It is a deficient approach to set the price and exclude yourself from the process. It is wise to allocate time in your schedule quarterly, as it is possible to save large sums from the system being reviewed. It is a yearly return of 8 to 15 percent. - Seek Out New Materials Proactively

Don’t let suppliers just be passive intermediaries waiting to deliver new materials. Each year, step outside the box to test new materials – you might discover alternative materials that provide better value. - Do Not Put All Your Eggs In One Basket

Maintaining 2 or 3 suppliers keeps the pressure on and helps to cultivate new ideas. This is about choice, and there is plenty of it. - Automate Where It Is Logical to Do So

Start small. Automate those areas that are labor-intensive and costly. Even the most rudimentary machines can assist greatly. - Use Metrics to Identify Better Opportunities

Analytics that analyze the design, source, and ship collaboratively can be counter-intuitive to savings, and provide better control and more efficient planning.

What Kind of Savings Can You Expect?

| Strategy | Time to See Impact | Savings Range |

| Packaging Reviews | 2-3 months | 8-15% |

| Supplier Additions/Review | 6-9 months | 10-15% |

| Sustainable Materials | 4-12 months | 5-12% |

| Targeted Automation | 3-6 months | Up to 25% |

| Data-Driven Decisions | 4-8 months | 5-8% |

Some Real-World Hurdles (And How To Beat Them)

Retooling means training new people, bringing onboard unscheduled suppliers, and managing price volatility. This is why flexibility and fostering deep supplier partnerships help. And thank goodness technology and rewards systems are streamlining this process.

Final Thoughts: Every Box Counts

For real wins, don’t think of packaging as an isolated expense, but as an integrated system. Balance design, materials, suppliers, and automation. The brands that dominate turn ceaseless evolution into a standard practice. Nobody is above having unprotected products. The product inside gets defended, the customers are defended, and the business stands to gain an amplified reputation.

The Rise of Paper Bags – How Sustainable Packaging is Shaping the Future of Retail for CPOs

The Rise of Paper Bags – How Sustainable Packaging is Shaping the Future of Retail for CPOs

The retail industry is undergoing a significant transformation driven by growing concerns for environmental sustainability.

As consumers become more eco-conscious, businesses are shifting towards sustainable packaging solutions.

One of the most prominent changes in recent years has been the move from plastic bags to paper bags.

This transition is fueled by a combination of consumer demand, government regulations, and corporate sustainability goals.

Retailers and Chief Procurement Officers (CPOs) are now prioritizing eco-friendly alternatives, such as paper bags, to reduce plastic waste, meet regulatory requirements, and enhance brand reputation.

This blog explores the environmental impact of plastic bags, the benefits of paper bags, and how they are shaping the future of sustainable retail.

The Environmental Impact of Plastic Bags

1. Plastic Pollution Crisis

Plastic waste is one of the biggest environmental challenges of our time.

According to the United Nations, approximately 300 million tons of plastic waste are produced globally each year, with a significant portion ending up in landfills and oceans.

Single-use plastic bags contribute heavily to this crisis, taking hundreds of years to decompose and releasing harmful toxins into the environment.

2. Microplastics and Ocean Waste

Discarded plastic bags are a major contributor to marine pollution. They break down into microplastics, which contaminate water sources and pose a severe threat to marine life.

Every year, millions of marine animals, including turtles, seabirds, and fish, die due to plastic ingestion or entanglement.

These microplastics also enter the human food chain, posing potential health risks.

3. Carbon Footprint of Plastic Bags

The production of plastic bags is highly energy-intensive, relying on fossil fuels.

The extraction, manufacturing, and transportation of plastic bags generate a significant carbon footprint, worsening climate change.

The process releases greenhouse gases, contributing to global warming and environmental degradation.

4. Government Bans & Restrictions

- Many governments worldwide have implemented bans or restrictions on single-use plastic bags to combat plastic pollution. Notable regulations include:

India’s Single-Use Plastic Ban (2022): Prohibits the manufacture and sale of plastic bags below a certain thickness.

- European Union Plastic Ban: Targets single-use plastics, including plastic bags, across member states.

- U.S. State Regulations: Several states, including California and New York, have banned plastic bags and imposed fees on alternatives.

These regulations are encouraging retailers to adopt more sustainable packaging solutions, making paper bags an attractive alternative.

Why Paper Bags Are the Future of Retail Packaging

The transition from plastic to paper bags is not just a trend—it’s a necessary shift towards a more sustainable future. Here’s why paper bags are the preferred choice for retailers:

1. Biodegradability and Recyclability

Unlike plastic bags, which take centuries to decompose, paper bags are biodegradable and can be recycled multiple times.

This reduces landfill waste and promotes a circular economy, making them an environmentally responsible choice.

2. Consumer Preference for Sustainable Packaging

Modern consumers are increasingly making purchasing decisions based on a company’s sustainability efforts.

Brands that adopt paper bags demonstrate their commitment to environmental responsibility, which can improve customer loyalty and brand image.

Studies indicate that eco-conscious consumers are more likely to support businesses that prioritize sustainable packaging.

3. Corporate Sustainability Initiatives

Many businesses are aligning their packaging strategies with corporate sustainability goals.

Retail giants like IKEA, Starbucks, and McDonald’s have already transitioned to paper-based packaging to meet their green objectives and enhance brand credibility.

4. Compliance with Regulations

Using paper bags helps businesses comply with environmental regulations and avoid penalties associated with plastic bag bans.

Staying ahead of regulatory requirements can provide a competitive advantage and enhance corporate social responsibility (CSR) efforts.

5. Durability and Innovation

Advancements in paper bag manufacturing have resulted in stronger, more durable options capable of withstanding heavy loads.

Laminated and water-resistant paper bags are emerging as viable alternatives to plastic bags in various retail sectors.

These innovations ensure that paper bags remain a practical and sustainable choice for businesses.

6. Branding and Aesthetic Appeal

Paper bags provide an excellent canvas for branding and customization. Businesses can print logos, messages, and eco-friendly certifications on paper bags, reinforcing their commitment to sustainability while enhancing brand visibility.

The Future of Sustainable Retail Packaging

The demand for sustainable packaging solutions is only expected to grow.

Paper bags are evolving to meet industry needs with improved durability, cost-efficiency, and custom branding options.

Some key trends shaping the future of paper bags include:

- Increased Use of Recycled Materials: More retailers are opting for recycled paper bags to further minimize environmental impact.

- Technological Advancements in Paper Production: Innovations in papermaking are leading to stronger, moisture-resistant paper bags.

- Customization and Branding: Paper bags provide an excellent canvas for brand messaging, allowing businesses to create visually appealing, eco-friendly packaging.

- Hybrid Packaging Solutions: Combining paper with other biodegradable materials for enhanced strength and usability.

How Moglix Packaging Helps You

At Moglix, we understand the importance of sustainable packaging in today’s retail landscape.

Our range of high-quality, customizable paper bags offers businesses an eco-friendly alternative to plastic while maintaining durability and brand appeal.

By choosing Moglix packaging solutions, you can:

- Reduce your environmental footprint.

- Comply with global sustainability regulations.

- Enhance your brand’s eco-conscious image.

- Provide customers with a responsible and stylish packaging option.

Moglix ensures that businesses can seamlessly transition to sustainable packaging solutions, supporting both operational efficiency and environmental responsibility.

Conclusion

The rise of paper bags in retail is a direct response to environmental concerns, regulatory changes, and shifting consumer preferences.

As businesses adapt to a more sustainable future, adopting paper-based packaging solutions will provide a competitive edge.

With continuous innovations in durability, recyclability, and cost-effectiveness, paper bags are set to play a crucial role in retail sustainability.

Retailers and CPOs who embrace this change will not only contribute to a cleaner planet but also strengthen their brand’s reputation in an increasingly eco-conscious market.

The future of retail packaging is green—and paper bags are leading the way!

Packaging for the Future: Sustainable Solutions in E-commerce

Packaging for the Future: Sustainable Solutions in E-commerce

In 2022, global e-commerce sales stood at $5.63 trillion which represents nearly 19 percent of retail sales worldwide. Forecasts indicate that over the next five years, the online segment will make up close to a quarter of total global retail sales. This provides a fillip to the e-commerce packaging market which has enjoyed a CAGR of 20% since 2017 and expects to grow further.

The growth will be led by packaging manufacturers who continue to innovate as per the needs of the market.

Reducing Carbon Footprints: The Cement Industry’s Path to Sustainability

Reducing Carbon Footprints: The Cement Industry’s Path to Sustainability

The global cement industry produces an estimated 4 billion tons of material yearly fueling infrastructure that shape our daily lives, while contributing whopping 7% of global emissions. With this, the industry stands at a critical juncture. The good news is that the cement industry is waking up to its responsibility and is taking bold steps towards a greener future, innovating eco-friendly cement and sustainable packaging solutions.

In the wake of this, the World Cement Association has announced its goal to reduce CO2 emissions by the cement industry by at least 25% by 2030.

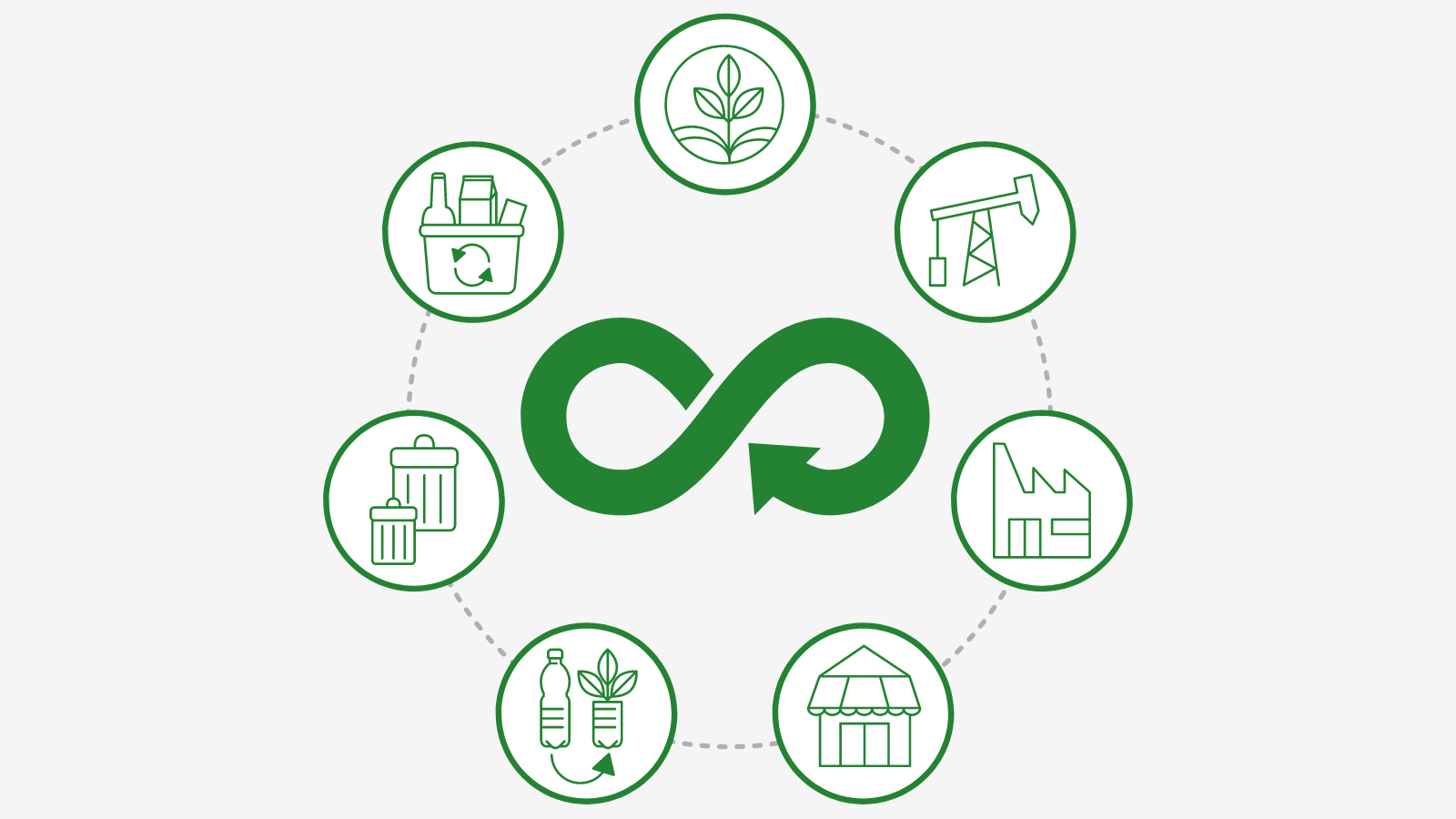

A closer look at corrugated box packaging: And why it is the future of a circular economy

A closer look at corrugated box packaging: And why it is the future of a circular economy

Why corrugated boxes fit perfectly into the narrative of a circular economy

The American Forest & Paper Association had some encouraging news to report last year; a colossal 91.4% of old corrugated containers (OCCs) were recycled in the U.S. in 2021. Also, corrugated packaging ranks among the most recyclable options elsewhere in the world. This makes it a natural choice to pursue a circular economy, where resources are used, reused, and recycled in a closed loop — thus preserving natural resources and minimizing waste and pollution.

But even beyond their recyclability alone, corrugated boxes are the ultimate expression of a circular economy because they are sustainable across the product life cycle, from manufacture to recycling. Here’s how.

Manufacture and production

Life cycle assessment reports reveal that corrugated box manufacturers in the U.S. have been increasingly switching to renewable energy sources and simultaneously reducing greenhouse gas emissions. Elsewhere in the world, too, corrugated box production is highly sustainable, and with good manufacturing practices we can get good strength with higher percentage of recycled content.

Even in the regions that rely on fossil fuels for box manufacture, it can be relatively easy to make the transition to green energy sources that are also highly sustainable. This makes corrugated packaging a distinct example of circularity at the production stage.

Supply chain sustainability

Throughout its product life cycle, corrugated packaging is an integral part of the supply chain in various industries across the globe. From food and beverages, e-commerce, and office supplies to more sensitive products like electronics and healthcare equipment, corrugated boxes are perfectly suited to house many goods.

Sustainability is one of the key reasons driving the popularity of this packaging material. This, coupled with other valuable characteristics like rigidity, customizability, and scalability, only strengthens the case for circularity in corrugated packaging.

Reuse and recycling

Among the most recycled materials on the planet, corrugated boxes remain sustainable even toward the end of their usable life cycle. However, this is an area that requires a fair bit of streamlining, mainly when the boxes are used in last-mile delivery.

Since many end users are unaware of the high recyclability quotient of corrugated boxes, the cartons are often misdirected to landfills and other wastelands, pulling down the overall percentage of packages that can be put back into circulation. Awareness programs and conscientiousness among end users can reverse this situation and further improve the impressive role of corrugated boxes in a circular economy.

Want to give your business an advantage in the race to circularity?

Making the switch to corrugated box packaging or other recyclable packaging wherever possible could be a great place to begin. Moglix can be your ally in this challenging yet crucial transformation to sustainable solutions. Our end-to-end packaging procurement solutions can make the journey to circularity easier and quicker for you. Visit our website to learn more.

The Top 8 Industries that Use Corrugated Box Packaging

The Top 8 Industries that Use Corrugated Box Packaging

Corrugated materials are among the most popular kings of box packaging used worldwide. Leading market researcher IMARC group pegged the size of the corrugated box market at $198 billion last year and expects the market to nearly hit the $230 billion mark by 2028.

A significant portion of this tremendous growth can be traced back to certain select industries that rely significantly on corrugated box packaging. Here are eight such market segments.

Food and beverages

Corrugated boxes are particularly suitable for packaging and storing food products because they offer a unique advantage — resistance to bacterial infections. Since they keep the food items fresh, germ-free, and safe, these cartons are widely used in the F&B sector.

E-commerce

Corrugated packaging is easily the backbone of the e-commerce industry owing to its various benefits, like easy customization. Cartons come in different sizes to suit a wide range of products in the e-commerce supply chain and can be personalized to reflect brand values.

Office supply and stationery

The office supplies market worldwide is expected to increase at a CAGR of 1.9%, from USD 130.5 billion in 2021 to USD 149.4 billion by 2028. Corrugated packaging is integral to this booming industry for reasons ranging from scalability to availability and longevity.

Textiles

Packaging for textiles and apparel needs to be attractive, fuss-free, and indicative of the brand’s unique signature. Corrugated packaging helps check all these boxes, making it one of the preferred solutions in the textile industry’s supply chain across the world.

Luxury goods

Corrugated packaging is the only rigid medium that can be cut and folded into infinite shapes and sizes. This unique blend of customizability coupled with strength has made it a trendy packaging solution in the luxury goods market.

Healthcare

Whether it involves transporting medicines and pills or sensitive and delicate medical equipment, corrugated box packaging can be ideal for many reasons. It is rigid, hygienic, and easy to manufacture in different shapes to pack equipment of different sizes snugly.

Electronics

Although it’s easy to overlook, electronic products can be extremely fragile. Therefore, nothing but the sturdiest and safest packaging will do when they are shipped over long distances and across borders. The electronics industry, it appears, has found its solution in corrugated packaging.

Hazardous materials

Corrugated packaging can also be made water-resistant and highly tolerant to temperature changes. These attributes are why it is a preferred packaging material for transporting hazardous materials, batteries, etc.

Need corrugated box packaging? The right packaging solutions can make procurement a breeze.

Most corrugated box packaging is 100% recyclable, making them an excellent choice if your business is keen on increasing its sustainability quotient. Moglix can make it easy to procure the best-corrugated packaging for your primary, secondary and tertiary packaging needs. Visit our website to learn more.