Packaging for the Future: Sustainable Solutions in E-commerce

Packaging for the Future: Sustainable Solutions in E-commerce

In 2022, global e-commerce sales stood at $5.63 trillion which represents nearly 19 percent of retail sales worldwide. Forecasts indicate that over the next five years, the online segment will make up close to a quarter of total global retail sales. This provides a fillip to the e-commerce packaging market which has enjoyed a CAGR of 20% since 2017 and expects to grow further.

The growth will be led by packaging manufacturers who continue to innovate as per the needs of the market.

A closer look at corrugated box packaging: And why it is the future of a circular economy

A closer look at corrugated box packaging: And why it is the future of a circular economy

Why corrugated boxes fit perfectly into the narrative of a circular economy

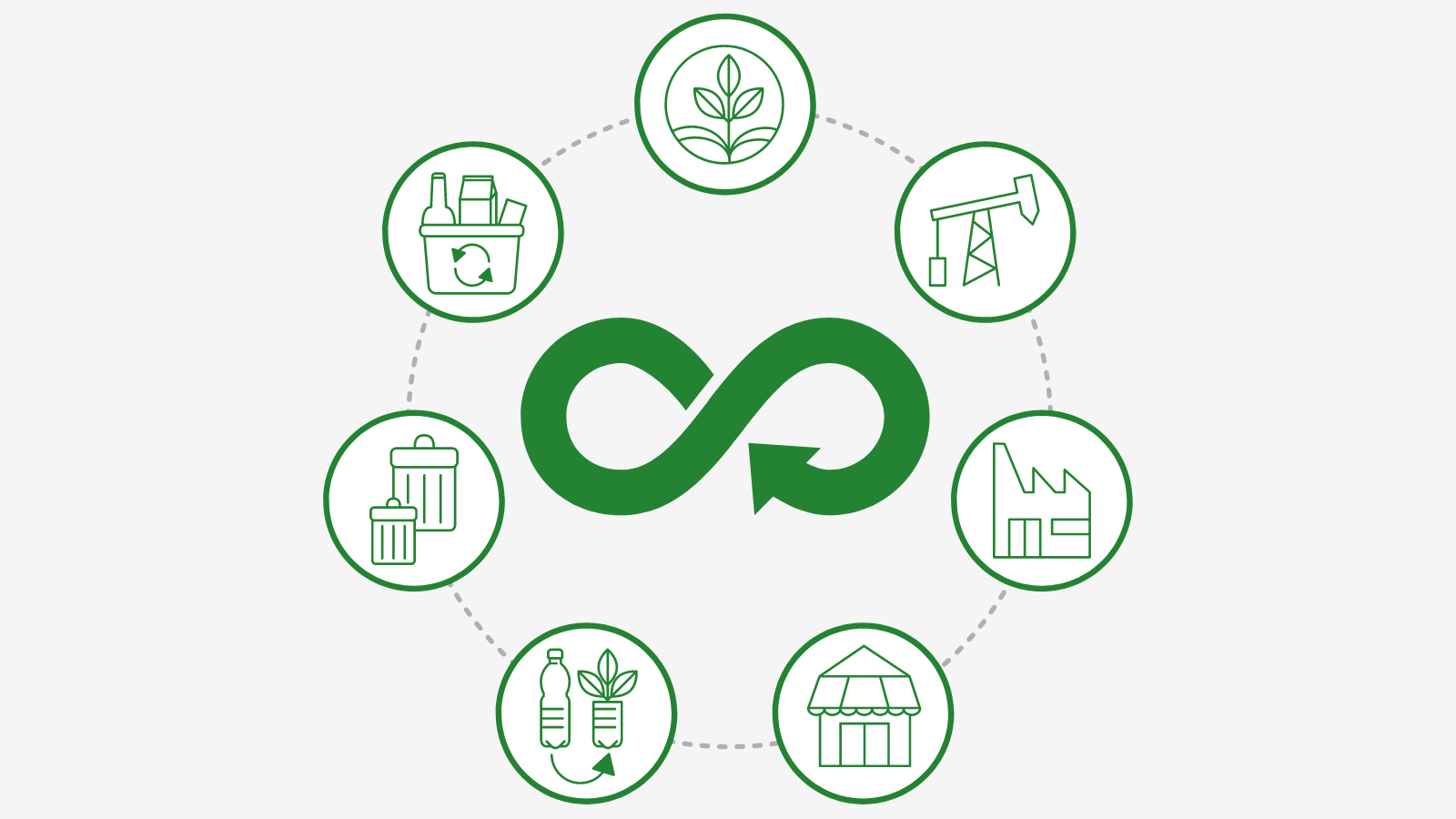

The American Forest & Paper Association had some encouraging news to report last year; a colossal 91.4% of old corrugated containers (OCCs) were recycled in the U.S. in 2021. Also, corrugated packaging ranks among the most recyclable options elsewhere in the world. This makes it a natural choice to pursue a circular economy, where resources are used, reused, and recycled in a closed loop — thus preserving natural resources and minimizing waste and pollution.

But even beyond their recyclability alone, corrugated boxes are the ultimate expression of a circular economy because they are sustainable across the product life cycle, from manufacture to recycling. Here’s how.

Manufacture and production

Life cycle assessment reports reveal that corrugated box manufacturers in the U.S. have been increasingly switching to renewable energy sources and simultaneously reducing greenhouse gas emissions. Elsewhere in the world, too, corrugated box production is highly sustainable, and with good manufacturing practices we can get good strength with higher percentage of recycled content.

Even in the regions that rely on fossil fuels for box manufacture, it can be relatively easy to make the transition to green energy sources that are also highly sustainable. This makes corrugated packaging a distinct example of circularity at the production stage.

Supply chain sustainability

Throughout its product life cycle, corrugated packaging is an integral part of the supply chain in various industries across the globe. From food and beverages, e-commerce, and office supplies to more sensitive products like electronics and healthcare equipment, corrugated boxes are perfectly suited to house many goods.

Sustainability is one of the key reasons driving the popularity of this packaging material. This, coupled with other valuable characteristics like rigidity, customizability, and scalability, only strengthens the case for circularity in corrugated packaging.

Reuse and recycling

Among the most recycled materials on the planet, corrugated boxes remain sustainable even toward the end of their usable life cycle. However, this is an area that requires a fair bit of streamlining, mainly when the boxes are used in last-mile delivery.

Since many end users are unaware of the high recyclability quotient of corrugated boxes, the cartons are often misdirected to landfills and other wastelands, pulling down the overall percentage of packages that can be put back into circulation. Awareness programs and conscientiousness among end users can reverse this situation and further improve the impressive role of corrugated boxes in a circular economy.

Want to give your business an advantage in the race to circularity?

Making the switch to corrugated box packaging or other recyclable packaging wherever possible could be a great place to begin. Moglix can be your ally in this challenging yet crucial transformation to sustainable solutions. Our end-to-end packaging procurement solutions can make the journey to circularity easier and quicker for you. Visit our website to learn more.

Circularity at Scale: Transforming the Packaging Industry

Circularity at Scale: Transforming the Packaging Industry

In its 2022 report, Circularity Gap Initiative revealed that only 8.6% of all material used by humankind is recycled, with the rest contributing to the rising waste levels. A circular economy prioritizing recycling and reuse is the need of the hour that entails keeping raw materials, goods, and services in circulation for the longest time possible, limiting the level of waste that gets generated on a global scale.

Most of the per capita waste generated globally comes from primary, secondary, and tertiary packaging; hence, the packaging is one of the focus industries that should adopt circularity. Circularity in packaging necessitates achieving sustainability along with good business sense for better adoption and longer haul.

Engineering a circular future with sustainable packaging

Engineering a circular future with sustainable packaging

India generates 3.5 million tonnes of plastic waste each year, as per data available from the Ministry of Environment, Forest, and Climate Change1. Moreover, India’s per capita generation of plastic waste has nearly doubled in the last five years. Besides adversely affecting the ecosystems, plastic pollution is linked to air pollution.

Against this backdrop, sustainable packaging could play a major role in curbing India’s carbon footprint as plastics comprise one-third of the carbon emissions in core manufacturing segments such as mining, metals and construction materials. The next highest contributors in this regard are energy, agriculture and related activities, logistics and HVAC, followed by other verticals.

Issues and Implications of Sustainable Practices

To mitigate the ravages of global warming, corporates across countries and continents are shifting to sustainable business practices that support a circular economy and advance efforts to curb climate change.